Axle Induction Hardening Equipment

Features:

1.Adopting DSP+IGBT Intelligent induction heating power.

2.Process monitoring screen and Data logging and Archiving

3.Application to Heat Treatment and Heating for many kinds of metal parts.

Product Detail

Application Video

Product Tags

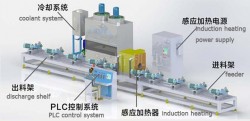

Axle Induction Hardening Equipment

Axle hardening equipment is suitable for the surface hardening and Induction heat treatment for the axle which own the larger diameter @ Ø30-Ø2000. According to customer requirements,the hardened layer depth can be controlled around 2mm–5mm. This equipment generally consists of intermediate frequency power supply, quenching transformers, all kinds of induction heating coils and quenching machine. Another thing, according to customer requirements,the hardening equipment can be equipped the PLC programming controller in order to achieve the whole process automatic control of the heating and hardening .

The axle induction hardening equipment features:

1.The workpiece with the larger diameter can be uniformly heated, high efficiency, stable quality

2.The heating layer depth adjustment range is large and the equipment power can equipped big.So according to customer requirements the power can be achieved 100KW-1000KW.

3.The equipment with PLC controller then can achieve mass production and ensure the stability of hardness and hardened layer.

Several advantages of induction hardening equipment :

1.Mature technology and quality assurance, please to feel free to use.

2.The inductor using profiling sensors then can scan hardening while water spaying at the same time.The hardness and hardening depth can meet the requirements.

3.To meet the 150mm diameter axle surface hardening requirements.

More information about the induction heating equipment,please feel free to contact with our company.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.