Forever Electromechanical is a professional manufacturer of continuous casting billet heating furnaces. The continuous casting billet heating furnace adopts advanced technology, imported high-quality materials, superior performance, high efficiency and energy saving, and perfect after-sales service. It is highly praised by customers of casting billet heating furnaces in Dalian. Due to the fact that Forever’s induction heating equipment is a non-standard product, please provide your specific requirements for the workpiece when consulting.

Configuration of Continuous casting billet induction heating furnace :

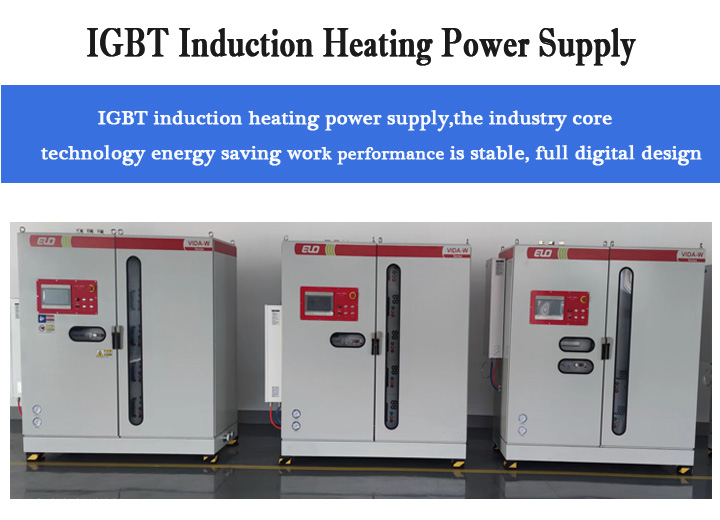

1. Resonant medium frequency induction heating power supply

2. Induction heating system for continuous casting billet heating furnace

3. Storage platform and automatic feeding device for pinch rollers

4. Quick discharge device for pinch roller

5. American Leitai dual color infrared temperature measurement system

6. Power transformer (optional according to customer’s actual needs)

7. Capacitor (optional according to customer’s actual needs)

8. Human machine interface PLC main operation console

9. Closed cooling tower

Working principle of continuous casting billet heating furnace:

This process cleverly combines casting and rolling, and compared to the traditional process of casting steel billets first, heating them in a Billet induction heating machine , and then rolling them, it has the advantages of simplifying the process, improving working conditions, increasing metal yield, saving energy, improving the quality of continuous casting billets, and facilitating mechanization and automation.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 11-21-2024