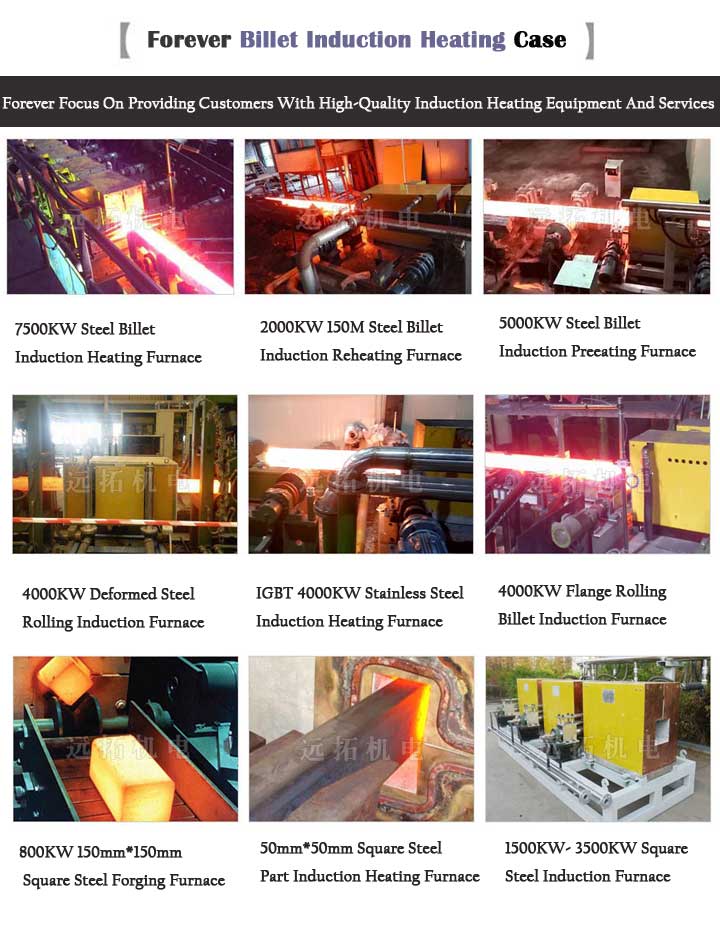

Hebei Forever Electromechanical has customized a 5000 kW steel billet heating furnace for customers, specifically designed for pre rolling reheating of 6000mm long, 150mm wide, and 150mm thick continuous casting billets. What are the characteristics of this Continuous casting billet heating equipment ? Let’s take a look together.

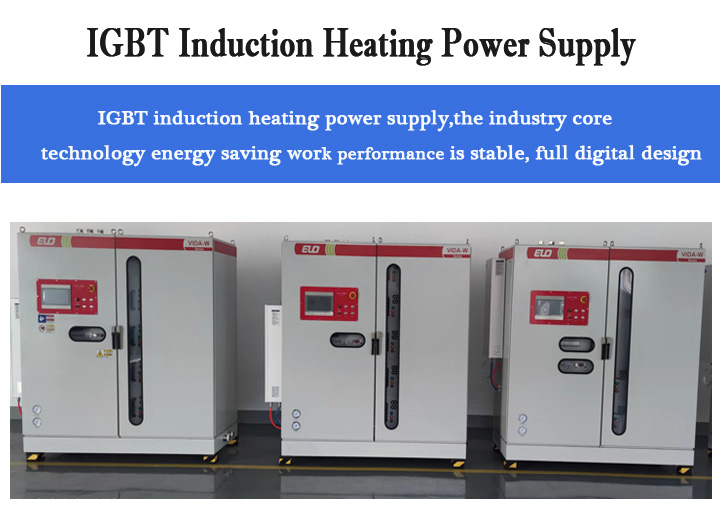

1. This heating furnace adopts electromagnetic induction heating technology, which can quickly heat continuous casting steel billets with a surface temperature of 800 ° C to a rolling temperature of 1100C.

2. By effectively utilizing the latent heat of continuous casting billets, the heating speed is fast, the energy consumption is low, and the heating speed can reach 15m/min. It is very suitable for docking with Continuous casting billet induction heating furnace, greatly improving production efficiency.

3. At the inlet and outlet of the equipment, an infrared temperature measuring device is equipped, and closed-loop control is achieved through a PLC control system.

4. When the temperature of the steel billet fluctuates, the system will automatically adjust the output power to ensure heating accuracy and stability.

Forever Electromechanical specializes in the production of Billet electric heating equipment, providing customers with systematic process development, complete engineering design, continuous casting billet heating furnace manufacturing, debugging and maintenance, after-sales service, etc. After treatment, the continuous casting billet heating furnace has no deformation and strong toughness. The entire production line is fully automated and intelligent. New and old customers are welcome to visit the factory and discuss business!

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 11-08-2024