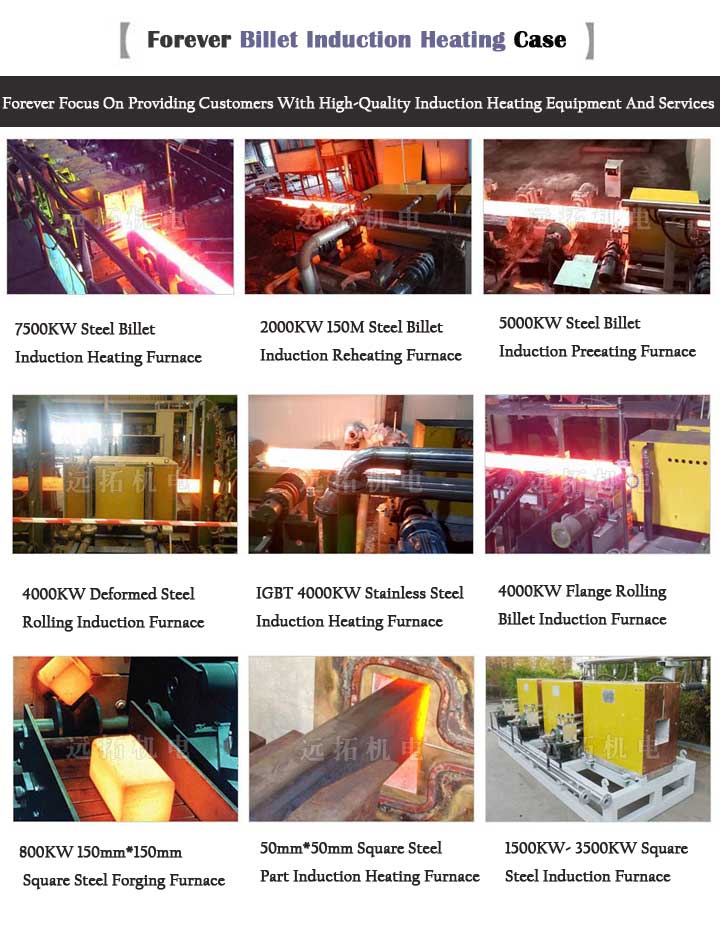

The fully automatic Continuous casting billet induction heating furnace designed by the company adopts PLC intelligent automatic program control throughout the process, which is safe, energy-saving, highly automated, with stable product quality, high production efficiency, and simple operation. If you choose Forever, you can enjoy superior prices because we are manufacturer produced and directly sold equipment. The continuous casting billet heating production line has won a good reputation among new and old users.

Characteristics of Continuous casting billet heating equipment :

1. Power supply system: Double rectified 12 pulse or 24 pulse KGPS1000-1000KW single intermediate frequency power supply can be used independently or multiple power supplies can be used in parallel. Install dedicated transformers on the equipment to reduce the impact of harmonics on the power grid. Users can use it with confidence, safe and reliable

2. Surface temperature before entering the furnace: ≥ 850 ℃

3. Control system: The entire heating process is automatically controlled by PLC, and production records such as heating quantity are displayed in a timely manner. This console is used alone, with a specially customized human-machine interface, highly user-friendly operation instructions, fully digital, high depth adjustable parameters, and a one click restore function, making it easy to operate.

4. Power supply requirements: Dual power transformers, 12 pulse rectifier power supply, can infinitely reduce harmonic pollution and improve work efficiency.

5. Feeding and guiding system: Each axis is driven by an independent motor reducer, equipped with multi axis drive and controlled by a single frequency converter to ensure synchronous operation of multiple axes. The components are selected from well-known brands, with reliable quality and stable operation. Using 304 non-magnetic stainless steel guide wheels to maintain moderate elasticity in the axial direction, in order to adapt to the allowable bending range of the steel billet.

6. All cabinets are sandblasted, sprayed with plastic, and painted. The waterways are made of thick walled stainless steel. The electric furnace for heating continuous casting steel billets is corrosion-resistant and has a long service life. The equipment is equipped with a large LCD temperature display screen (convenient for on-site personnel to observe and display data)

7. The use of the American Raytheon temperature measurement device ensures uniform temperature heating and no deformation or cracking of the billet.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 01-11-2024