The steel pipe induction annealing machine is customized for Tianjin Petroleum Equipment Company. This production line is designed to annealing a variety of metal pipes, including 140mm diameter steel, round, round, seamless, seamless, thick, thin-walled steel and circular steel pipes. It not only has a wide range of applications, but also has the characteristics of high efficiency, energy saving and environmental protection.

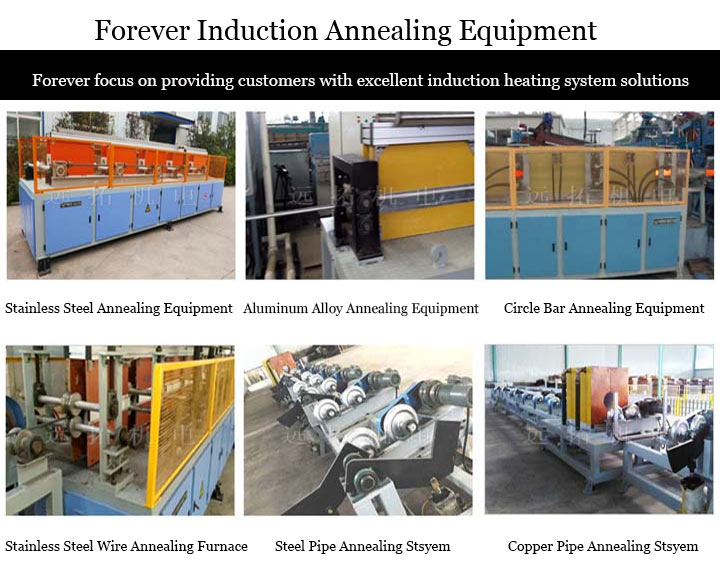

The Stainless steel pipe annealing production line consists of several key parts, including conveying system, heating system, heat treatment system, cooling system, control system and safety protection system. Each system has its own unique functions, working together to ensure the smooth operation of the production line.

The conveying system is responsible for conveying the metal pipes to each treatment station to ensure fluency and automation in the production process; the heating system adopts advanced electric heating element heating technology to heat the pipes to the preset insulation temperature; the heat treatment system ensures that the pipes are heated to the preset temperature to distribute the internal temperature and achieve better heat treatment effect; The cooling system can quickly cool the pipes to room temperature to prevent deformation and cracking. As the core of the control system of the whole annealing heat treatment production line, it adopts advanced PLC (programmable logic controller) and industrial control machine control mode, which can realize the automatic control of pipe movement, heating, insulation and cooling, improve the production efficiency and reduce the operation difficulty. High quality induction heat treatment equipment to find Hebei Yuantuo mechanical and electrical, professional manufacturers, value trust!

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Post time: 08-08-2024