Grinding rods are used in cement plants, power plants, mines, quartz sand plants, silica sand plants, sand gasification, coal chemical and other rod mills and coal mills. The steel bars used in the market are rolled by steel mills. The technical requirements are not high, the wear-resistant effect is extremely poor, and the consumption is unlimited when used. The national resources are wasted.

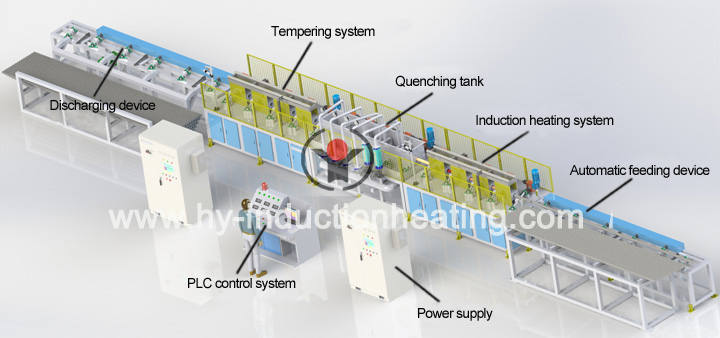

For a consumable product (rolled steel bar) in the market, we, Forever electromechanical manufacturer, have developed a grinding bar quenching and tempering production line for grinding bar quenching and tempering. The durability of the grinding bar produced by our grinding bar quenching and tempering line is 4 & mdash& mdash; 6 times, effectively saving steel consumption. Technical parameters of Grinding rod induction quenching and tempering line of our Forever electromechanical manufacturer:

● power supply system: kgps160kw-1000kw / 0.5-2.5khz.

● conveying roller table: the included angle between the roller table axis and the workpiece axis is 18-21 & deg;, The workpiece rotates by itself and advances at a constant speed to make the heating more uniform. The roller table between furnace bodies is made of 304 non-magnetic stainless steel and water cooled. The roller table of other parts is made of 45 steel and surface quenched.

● roller table grouping: the feeding group, the sensor group and the discharging group are controlled independently, which is conducive to continuous heating without generating gaps between workpieces.

● temperature closed-loop system: both quenching and tempering adopt American Leitai infrared thermometer and form a closed-loop control system with German Siemens S7 to accurately control the temperature.

● industrial control computer system: it displays the status of working parameters at that time in real time, and functions such as workpiece parameter memory, storage, printing, fault display and alarm.

▲ energy conversion: the self tempering method after quenching is adopted, and the power consumption per ton is 280-320 degrees.

FOREVER Electromechanical Factory specializes in providing customers with various types of automatic intelligent Induction heating machine solutions and services. Welcome new and old customers to visit the factory and call for consultation

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Post time: 08-17-2022