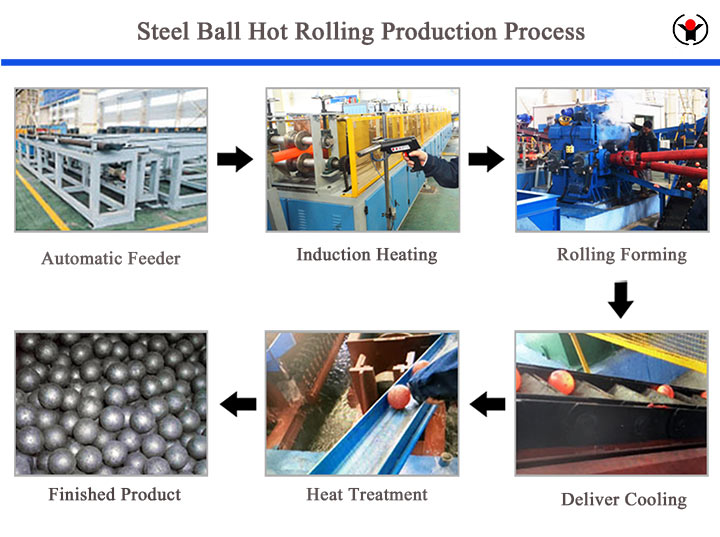

The steel ball hot rolling heating furnace usually uses medium frequency induction heating to heat the wear-resistant steel balls. This heating method is based on the principle of electromagnetic induction, which heats metal materials through an alternating magnetic field generated by an induction coil. When the wear-resistant steel ball is placed in the induction coil and passes through, the alternating magnetic field generates eddy currents inside the steel ball. These eddy currents generate heat energy when flowing inside the steel ball, quickly heating it to the temperature required for rolling.

The advantages of steel ball hot rolling production line include fast heating speed, high energy efficiency, uniform heating, and easy automation control. Due to the lack of direct contact with the heating element during the heating process, energy loss can be reduced and thermal efficiency can be improved. In addition, induction heating does not produce open flames or smoke, is environmentally friendly, and meets the requirements of modern industry for environmental protection.

The production technology of wear-resistant steel balls is constantly improving to meet the needs of larger scale and higher efficiency production. For example, research has developed rolling technology suitable for φ 125mm steel balls and systematically studied the steel ball induction hot rolling system. The development of these technologies helps to improve the performance of wear-resistant steel balls while reducing production costs and environmental impact.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-08-2025