The steel ball induction heating production line for bar rolling is operated in the Liaoning steel ball production workshop. The steel ball production equipment is customized and produced by Hebei Forever Electromechanical Equipment Manufacturing Co., Ltd. according to the actual needs of Benxi Steel Union customers.

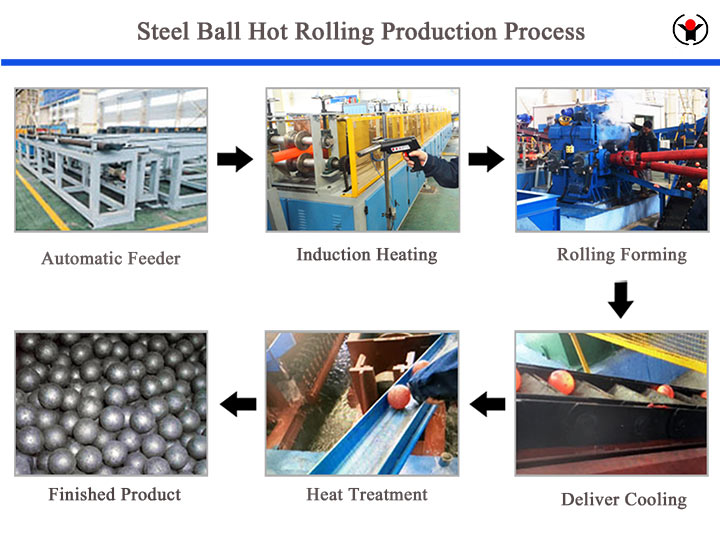

The steel ball hot rolling furnace production works in this way:

1. After the raw materials enter the factory, they undergo material and diameter testing and analysis.

2. The defective steel ball material is heated to a suitable temperature in an induction heating furnace before rolling.

3. After being fed into the steel rolling mill, the red hot steel billet rotates and advances between two rollers with special spiral passes, and is continuously rolled into steel balls. Each steel ball rolling mill can produce 40-120 steel balls per minute.

4. When the steel ball hot rolling equipment is cooled to the quenching temperature, it immediately enters the online heat treatment equipment for quenching. After quenching, it is cooled to a suitable temperature (below 50C) and enters the online continuous tempering furnace for stress relieving and tempering treatment, allowing the steel ball to achieve high and uniform hardness.

5. After passing the inspection, the products are packaged and sent to the finished product warehouse for delivery to the customer.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China;Glad to be your business partner in induction heating field.

Post time: 06-25-2024