The Rebar steel induction heat treatment furnace is a process of heating, quenching, tempering, and insulation of rebar.

Working process of Deformed bar hardening tempering furnace

The storage rack is equipped with automatic feeding, variable frequency roller feeding, rotating heating, rotating water spray quenching treatment, rotating tempering treatment, variable frequency roller output, and material receiving. The entire quenching and tempering heat treatment process of threaded steel is automatically completed by PLC, and various parameters of the production process are recorded throughout the process, including the operation status, temperature, and output of the series resonant intermediate frequency power supply. The rebar quenching and tempering equipment has a one click restoration function.

Process and advantages of Thread bar heat treatment machine :

1. The entire heating, quenching, and tempering process of threaded steel is carried out by the threaded steel rotating through the support rollers (the variable frequency support rollers for heating, quenching, and tempering are directly driven by variable frequency motors and reducers).

2. Install the American Raytheon infrared temperature measurement device and use a large display screen to display the heating temperature in real time, making it easy for operators to observe and quality inspectors to record

3. The stainless steel water tank and quenching spray ring are made of stainless steel. The shaft and wheel of the spray device are made of stainless steel, and a visual flow meter is installed for easy adjustment and recording of the spray process. A water temperature measuring device is installed to display the water temperature in real time.

4. The hardness of the products produced by the rebar quenching and tempering heat treatment equipment is uniform, and there is no deformation or cracking phenomenon in the products,

5. Equipment installation intelligent energy metering system: Real time display of the operating power of the threaded steel quenching and tempering heat treatment equipment, and recording of the electricity consumption for the current shift or cumulative batch, facilitating cost accounting.

6. Energy saving and environmentally friendly, high production efficiency, and high finished product quality.

7. After modulation heat treatment, the hardness of the threaded steel is uniform and meets the customer’s requirements.

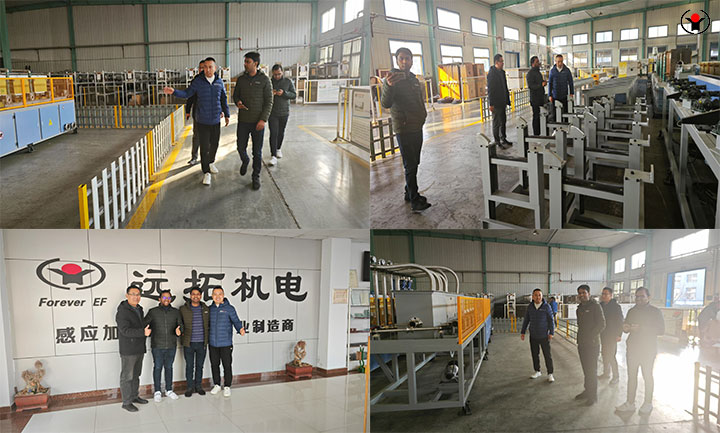

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-21-2025