When choosing a suitable steel ball hot rolling induction furnace, you need to consider the following key factors:

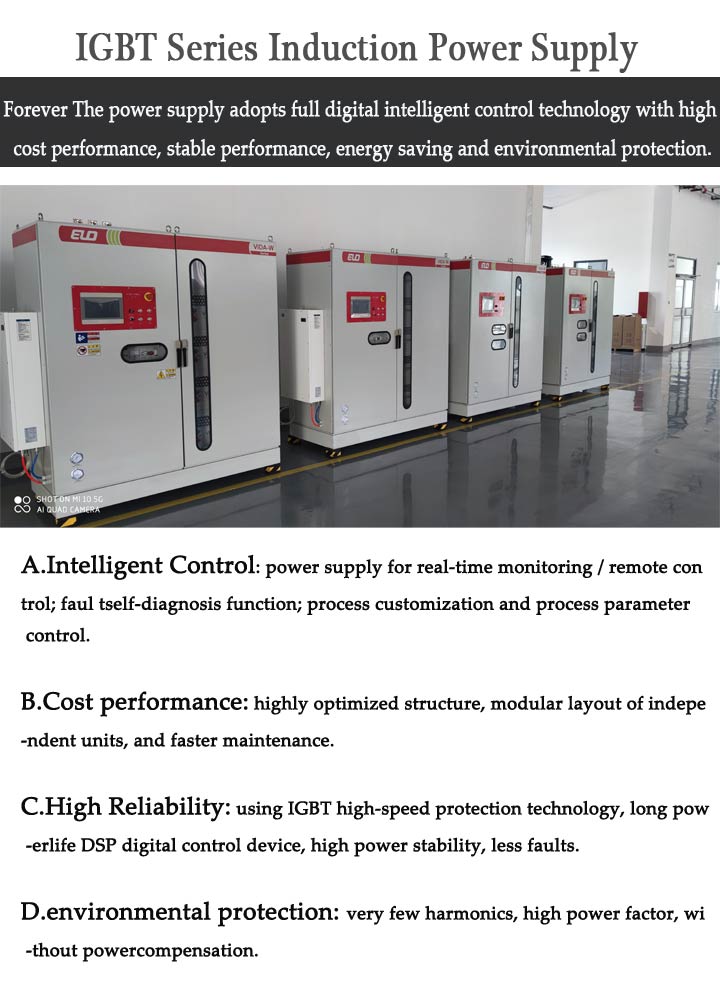

◊ Medium frequency heating power supply : Select the appropriate power level of the medium frequency power supply according to the production capacity requirements, usually ranging from 200KW to 15000KW.

◊ Steel ball material: Ensure that the induction furnace is suitable for the steel ball material you need to roll, such as B2, B3, B6, 70Cr2, 75Mncr, 65Mn, 60Mn, GCr15, 40Cr, 45 #, etc.

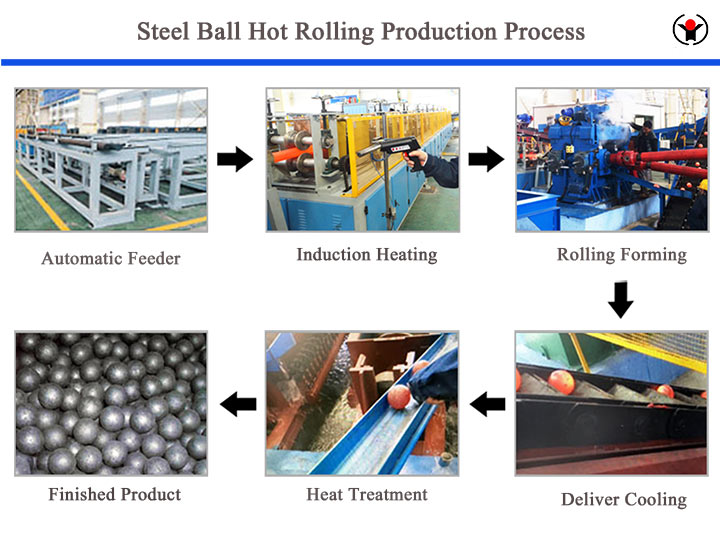

◊ Steel ball production: Based on your hourly production requirements, choose an induction furnace that can meet the production volume, generally ranging from 0.2-20 tons/hour.

◊ Sensor design: Choose sensors with variable pitch and temperature gradient design to improve heating efficiency.

◊ Automation level: Consider the automation level of the equipment, including PLC control systems and touch screen or industrial computer systems, which can simplify operations and improve production efficiency.

◊ Temperature control: Ensure that the induction furnace is equipped with a precise temperature control system, such as an infrared temperature measurement device, to ensure consistency in the heating temperature of the steel balls.

◊ Energy efficiency and conservation: Choosing equipment with high energy efficiency ratios and energy-saving performance can help reduce operating costs.

◊ Cooling system: Check whether the design of the cooling system can adapt to long-term operation and different working environments to ensure the stability and safety of the steel ball hot rolling heating furnace .

◊ Maintenance and service: Consider the maintenance services and technical support provided by manufacturers, which are crucial for ensuring the long-term stable operation of equipment.

◊ Application requirements: Select the most suitable equipment model and configuration based on your specific production environment and process requirements.

When choosing a steel ball hot rolling induction furnace, it is recommended to cooperate with professional equipment suppliers or process engineers to obtain more detailed technical support and customized advice. At the same time, pay attention to the latest market information and technological developments to ensure that the selected equipment can meet current and future production needs.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 09-29-2024