Hebei Forever Electromechanical specializes in providing steel plate induction hardening furnaces, PLC fully automatic intelligent control, closed-loop temperature control for steel plate quenching furnaces, uniform heating, no overburning, no deformation, no cracks, and quality assurance.

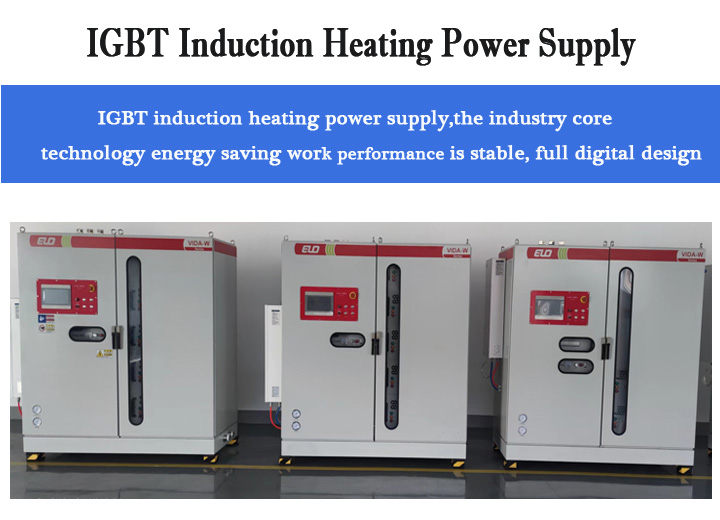

The power supply of the steel plate hardening equipment adopts fully digital intelligent control technology:

Intelligent control: The power supply can monitor and remotely control the operating status in real-time; Fault self diagnosis function; Process customization and process parameter control, etc.

High cost-effectiveness: highly optimized structure, modular layout of independent units for faster maintenance, and easy expansion of power supply with development.

High reliability: Adopting IGBT high-speed protection technology, with long power supply life and DSP digital control devices, the power supply has high stability and few faults.

Energy saving and environmental protection: minimal harmonics, high power factor, no need for power compensation.

The working performance of Steel plate induction quenching furnace :

★ Steel plate heat treatment and quenching equipment roller conveyor with dual pressure rollers, each axis is driven by an independent motor reducer and controlled by an independent frequency converter, allowing the steel plate to move flexibly and quickly on the track, ensuring uniform heating of the workpiece. The steel plate heat treatment and quenching equipment adopts a water-cooled roller variable frequency dragging method for feeding, and the workpiece is transported at a constant speed. Induction devices are installed on the conveyor line to ensure smooth passage of the plate through the rollers.

★ The frame of the conveyor mechanism for steel plate heat treatment equipment has sufficient strength and rigidity. In order to facilitate equipment installation, adjustable feet are installed at the bottom of the frame to make the equipment more aesthetically pleasing as a whole.

★ Using American Leitai thermometer to control temperature, real-time display of current temperature, and more uniform heating.

★ We have designed a sturdy and durable roller conveyor electrical isolation system to solve the problem of damage to workpieces in bulk. Steel plate quenching furnaces are mainly used in the metallurgical industry and mechanical manufacturing industry. The steel plate quenching furnaces produced by Yuantuo have strong automatic control, complete self-protection functions, and the power supply system can increase the power factor to above 0.93. They belong to reciprocating frequency induction heating furnaces, which save energy and reduce costs.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-23-2025