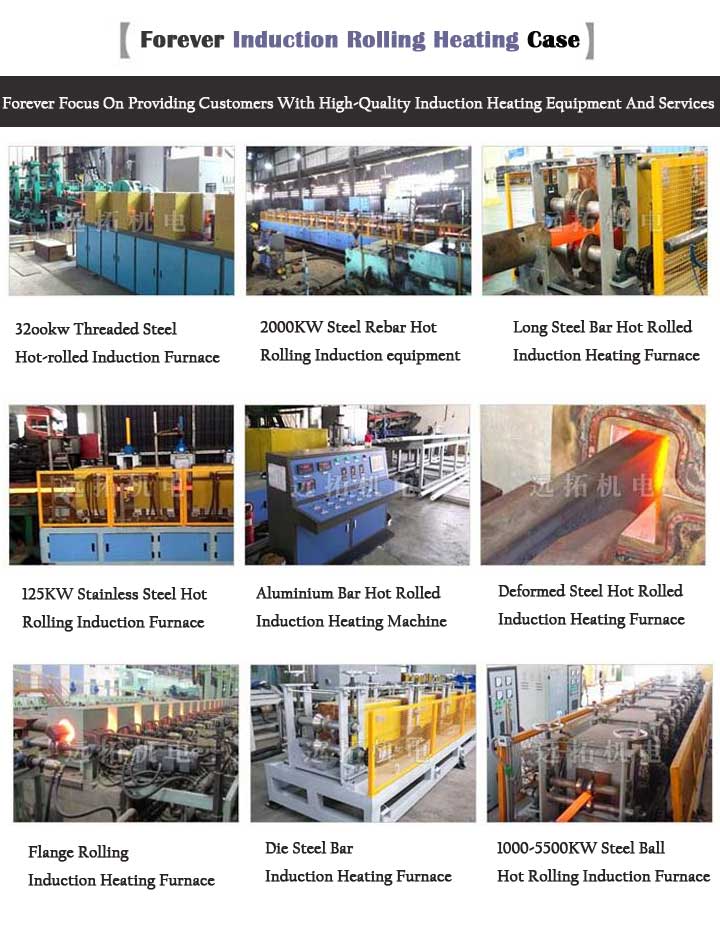

Looking ahead, grinding steel balls are commonly used to grind materials in fields such as mining, cement, and coal chemical industry. So, which steel ball hot rolling production line is more suitable for producing steel balls with a diameter of 120mm?

Understanding of fully automatic steel ball hot rolling furnace

The process of producing steel balls is to heat the round steel to 950-1050 degrees, and then use a diagonal rolling mill or forging hammer for treatment. The specific process is as follows:

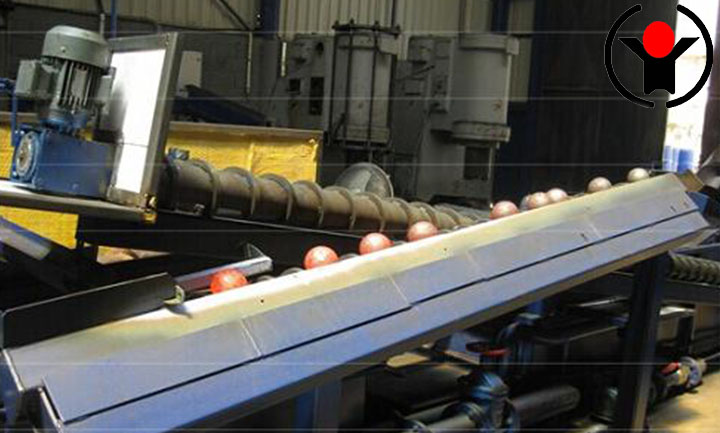

Steel ball rolling heating furnace

Specification: ∅ 20mm – ∅ 120mm.

Round steel materials: 65Mn, 60Mn, 50Mn, B2, B3, 40Cr, 45, etc.

Round steel length: 6000mm.

Heating method: medium frequency induction heating furnace

Heating temperature: 950~1050 ℃

Air hammer forging steel ball equipment

Air hammer forging steel balls is a traditional wear-resistant steel ball forging production process that uses an air hammer to forge the raw materials to the required deformation, increase the forging ratio, and make the internal structure of the ball mill steel balls more dense, improve toughness and density, improve wear resistance, and reduce crushing rate. It can produce forged steel balls with a diameter of 100-150mm.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 11-23-2023