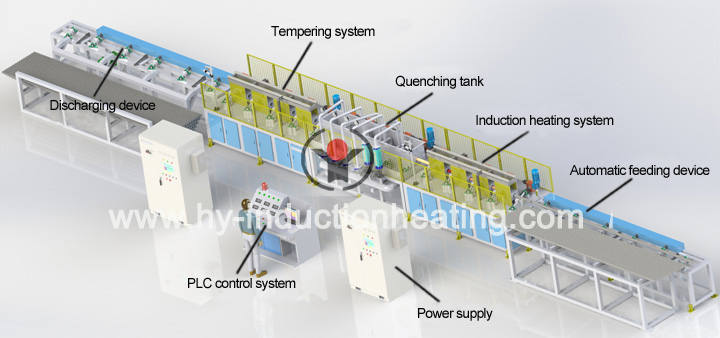

Quenching and tempering furnace for bar

Features:

| Bar diameter | ø45-100 mm |

| Bar length | 2000-6000mm |

| Control system | PLC control |

| Process | Quenching, tempering |

Product Detail

Application Video

Product Tags

Specialized in producing quenching and tempering furnace for bar, Forever engineer team is familiar with various grades of steel heat treatment process. We will help you choose the most suitable quenching and tempering furnace for bar as per our 13 years’ experience.

Site case for Quenching and tempering furnace for bar

| Product name | Quenching and tempering furnace for bar |

| Brand | Forever |

| Material | EN8D(45 steel), EN8, EN19(42CrMo), SAE 4140(42CrMo), EN18, 40Cr, EN24(40CrNiMoA) |

| Bar diameter | ø45-100 mm |

| Bar length | 2000-6000mm |

| Control system | PLC control |

| Process | Quenching, tempering |

| Quenching temperature | 920-930℃ |

| Tempering temperature | 680-700℃ |

Inductor Parameter Design for quenching and tempering furnace for bar

According to the different parameters of the workpiece,our engineer will optimizatized design different inductor group to get the effect of high efficiency. The inductor for tempering will increase the inductor quantity and adding tempering holding box to get better structure after temepring,ensuring the workpiece performance meets the requirements.

Mechanical conveying part

Adopting domestic brand Jiangsu Guomao GR67 series hardened motor reducer as the driving power; Using 40Cr steel as the feeding roller which is surface quenched; The rollers between inductors adopts 304 non-magnetic stainless steel and cooling by inputting water

The features for Quenching and tempering furnace for bar

● The quenching and tempering furnace adopts Forever new design and energy saving generator with very small deformation.

● Fast heating can make the bar obtain required temperature in a very short period of time, so that there is very small oxidation skin.

● According to request for quenching depth and hardness, our quenching and tempering furnace can adjust the working power and frequency to meet users’ requirement.

● Easier to achieve mechanization and automation, controlled by PLC man-machine interface, which can save labor and increase production efficiency.

● Easy to use, simple operation, can start or stop at any time.

● Support automatic & manual operation.Support 24 hours continuous work.

● Equip with United States Raytek double color infrared thermometer, real-time display heating temperature.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.