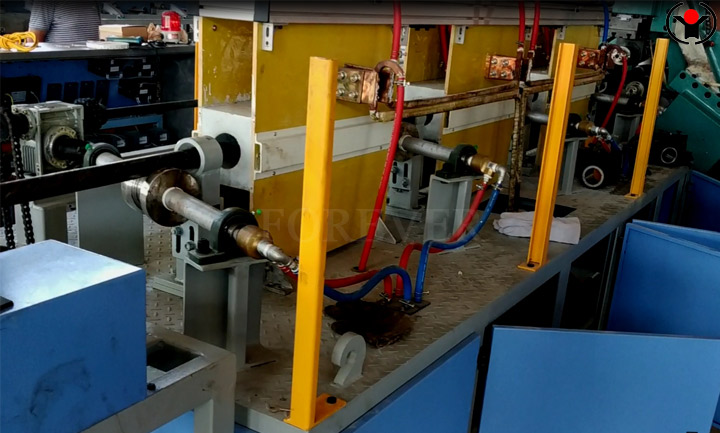

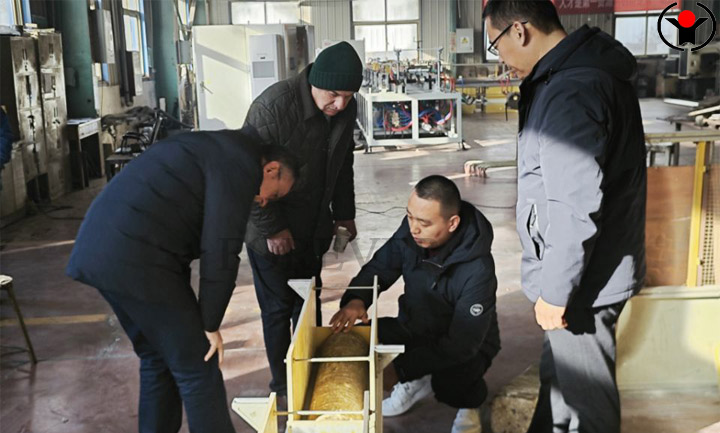

The steel pipe induction annealing equipment is a specialized equipment produced by Yuantuo Electromechanical Factory for induction heat treatment of large-diameter pipes. The pipeline annealing furnace consists of an intermediate frequency power supply, a PLC intelligent operation console, a feeding rack, a discharging rack, a heating system, an air cooling system, etc.

Steel pipe annealing furnaces are mainly used in heat treatment workshops for the production of large pipelines such as oil, natural gas, heating pipelines, etc. Typical application cases of oil pipelines include the West East Gas Pipeline, subsea oil pipelines, and offshore oil platforms.

Steel pipe annealing furnace is an equipment used for heat treatment of steel pipes, with the main features including:

Heating and cooling control: The steel pipe annealing furnace can heat the steel pipe to an appropriate temperature and maintain insulation, and then achieve annealing treatment by controlling the cooling rate to eliminate structural defects, improve structural uniformity, refine grains, enhance material mechanical properties, and reduce residual stress.

Temperature and atmosphere uniformity: The furnace is equipped with strong stirring fans and reasonably arranged electric heating elements to ensure uniform temperature and atmosphere distribution, thereby achieving high-quality annealing effects.

High efficiency and automation: Steel pipe annealing furnaces usually use roller type synchronous transmission and variable frequency speed control motors to ensure the smoothness and reliability of the transmission. High degree of automation enables continuous production and improves production efficiency.

Environmental protection and surface quality: The design of the Pipe induction annealing machine focuses on environmental protection, and the treated steel pipes have a smooth surface, uniform hardness, and no oxidation phenomenon, meeting high-quality standards.

Durability and maintenance: The supporting bearings are special high-temperature resistant bearings, ensuring the stable operation and long service life of the equipment. There is a debris removal port designed below the furnace to keep the furnace clean and improve product quality.

Control system: The electrical control system adopts a programmable logic controller (PLC), which can be used in conjunction with a computer to monitor the production line, achieve precise temperature control, and automate the management of the production process.

Safety: The steel pipe annealing furnace is equipped with a safety interlock and alarm system to ensure the safety of operators and the normal operation of equipment.

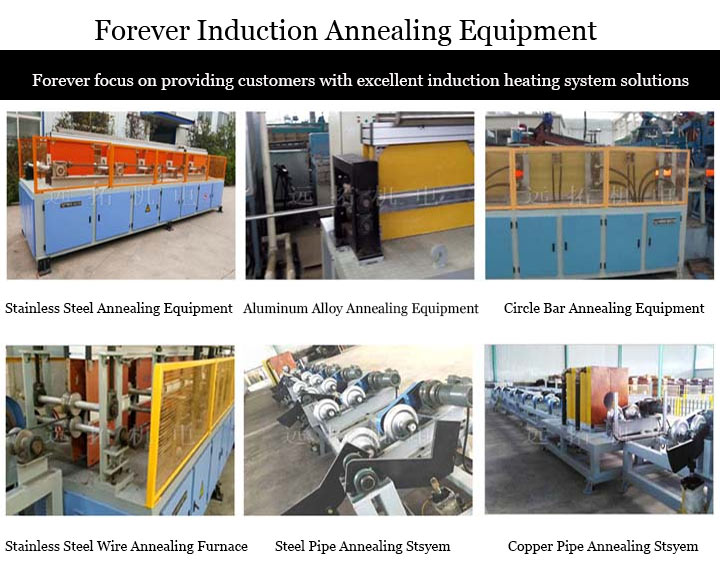

Applicability: The steel pipe annealing furnace is not only suitable for annealing carbon steel pipes, but also for bright heat treatment of stainless steel pipes, alloy steel pipes, copper pipes and other materials, meeting the heat treatment needs of different materials.

These characteristics make Steel pipe annealing furnaces an important heat treatment equipment in the metal processing industry, which can significantly improve product quality and production efficiency.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China;Glad to be your business partner in induction heating field.

Post time: 10-13-2024