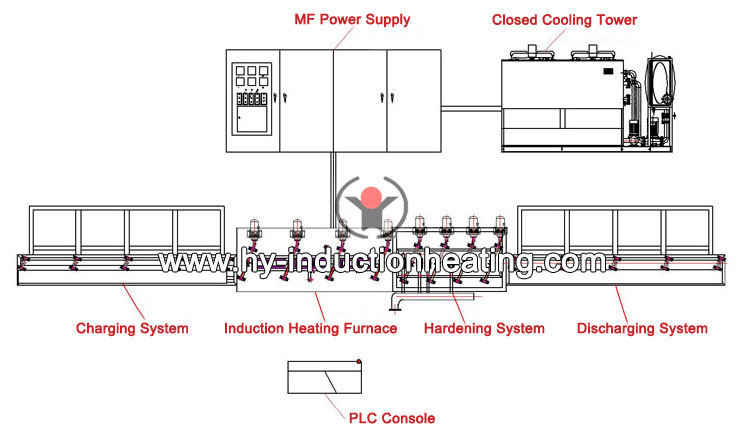

Characteristics of large steel bar induction hardening furnace :

1. The induction heater adopts a quick change joint structure to facilitate the replacement of the inductor

2. The surface quenching furnace inductor of the large steel bar is made of high-quality knotting material.

3. The water-cooled guide rail inside the sensor is made of 304 stainless steel material, and the surface is sprayed with a layer of drill tungsten material or stacked with tough stainless steel strips to ensure high efficiency and durability. There is a sliding groove at the interface between sensors to facilitate the cleaning of oxide skin.

4. The cross-sectional area of the sensor wire enclosure, busbar, and connecting wires is large enough to reduce the heating degree of the workpiece.

5. The internal connection of the coil of the Large bar heating system is stable and reliable, and the inductor is manufactured strictly according to the process requirements. Before assembly, it is subjected to high-pressure leakage testing.

6. A temperature switch is installed on the coil of the sensor, which automatically shuts down when the water temperature exceeds 65 ° C. When not working, the condensed water inside the sensor wire black can be discharged through compressed air.

7. The feeding end of the induction heater adopts a cylinder feeding mechanism to ensure uniform and consistent conveying speed.

8. The normal service life of the sensor wire enclosure is more than 5 years

9. The frequency live wire inductor in the large steel rod adopts a parallel variable turn design, and the temperature of the long steel rod gradually increases from the feeding end to the discharging end, to ensure that the long steel rod does not produce small cracks, overheating and other defects during the heating and quenching process. The cross-sectional area of the inductor coil, busbar, and connecting wires is large enough to reduce heating.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 10-26-2023