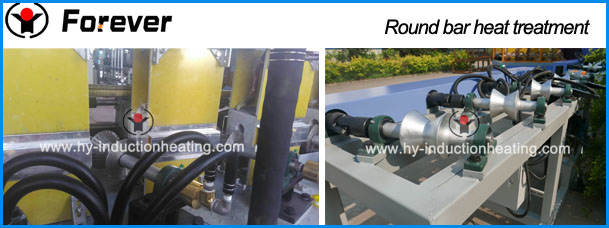

Continuous hardening and tempering furnace for round bars

Currently the most widely used surface heat treatment is induction heat treatment, it can be applied to the workpiece quenching, tempering, normalizing, quenching, diathermy and so on. For mechanized large-scale production, user can achieve unmanned operation through computer control.

Firstly, What is the advantages of continuous hardening and tempering furnace for round bars?

1. Shorten the production cycle and improve working conditions.

2. Improve the level of production organization, improve product quality.

3. Induction heating equipment can save 2% than the flame heating furnace , while improving the service life of forging mold.

4. As the induction heating does not produce smoke and dust, it clean the workshop environment.

5. Heating time is short, high efficiency, induction heating efficiency can be up to 60% -70%.

Secondly, what does Forever produce for continuous hardening and tempering furnace?

1. Oil drill pipe hardening and tempering heat treatment equipment

Mainly used for petroleum pipe (oil drill pipe, drill collar) heat treatment, drill pipe end thickening, heating, wear-resistant welding with preheating, elbow heating, gas (oil) pipe anti-corrosion coating heating.

2. Long-axis intermediate frequency hardening and tempering heat treatment equipment

For larger diameter shaft (workpiece diameter Ø30-Ø500) hardening and tempering heat treatment.

3. Steel bar intermediate frequency quenching heat treatment production line

Mainly used for car steering gear, rack rough (bar) and a variety of shaft-type rough billet continuous hardening and tempering.

4. Prestressed steel bar heat treatment equipment

5. Plate continuous hardening and tempering heat treatment production line

The production line has PLC centralized control, work safety, stability and reliability.

With the development of industry and improvement of hardening and tempering furnace technology. Continuous hardening and tempering furnace will bring economic benefits and a good working environment.

Contact person: TomWang

Email: yuantuodianlu@163.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Post time: 12-28-2017