The metal heat treatment is a working procedure for improving the mechanical properties of the metal workpiece, and the hardness, the strength and the wear resistance of the metal workpiece can be improved by heat treatment.

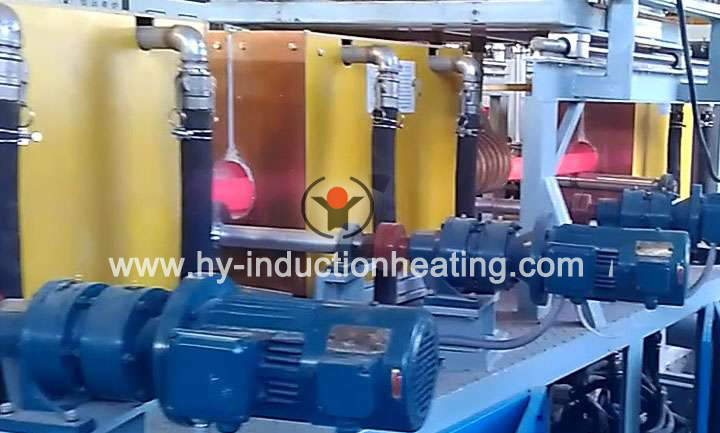

Heat treatment usually consists of three processes: heating, heat preservation and cooling, sometimes only heating and cooling. These processes are connected to each other and cannot be interrupted. Heating is one of the important processes of heat treatment. There are many heating methods for heat treatment of metals. Charcoal and coal are used as heat sources, and then liquid and gas fuels are used. Electrical applications, induction heating equipment makes heating easy to control, and no environmental pollution. These sources of heat can be heated directly or indirectly through molten salt or metal or even floating particles.

When the metal is heated, the workpiece is exposed to air and often oxidized and decarburized (that is, the carbon content on the surface of iron and steel parts is reduced), which has a negative effect on the surface properties of the parts after heat treatment. Therefore, metals should usually be heated in controllable or protective atmosphere, molten salt and vacuum, and can also be heated by coating or packaging.

The alloy is heated to the high temperature single-phase region to keep constant temperature so that the excess phase is fully dissolved into the solid solution and then cooled rapidly to obtain the heat treatment process of the supersaturated solid solution. A heat treatment process in which the screw sub-eutectic steel workpiece is heated to 20 / 40 degrees above AC3 for a period of time and then cooled in air with the furnace cooling slowly (or buried in sand or lime) to less than 500 degrees.

Metal heat treatment is one of the important processes in mechanical manufacturing. Compared with other machining processes, heat treatment generally does not change the shape of the workpiece and the chemical composition of the whole, but by changing the microstructure of the workpiece. Or change the chemical composition of the surface of the workpiece to give or improve the performance of the workpiece. Its characteristic is to improve the internal quality of the workpiece, which is generally not visible to the naked eye.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-06-2019