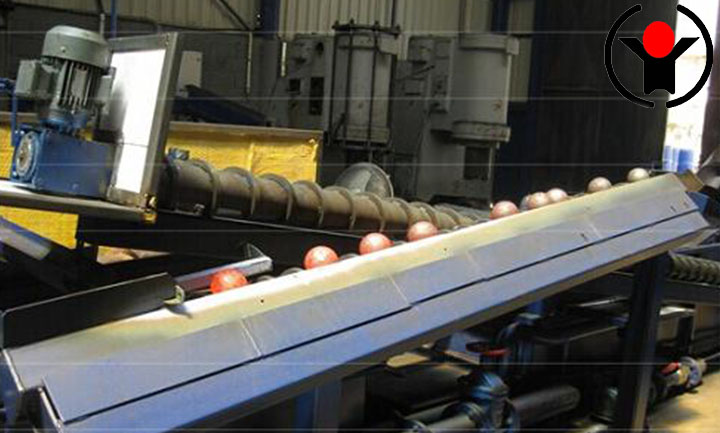

Features of Forever Electromechanical Round Steel Heating steel ball hot rolling equipment :

1. The production efficiency of the round steel heating steel ball production line is high. Taking the processing of 60 steel balls as an example, 70-80 steel balls can be produced per minute. 7 tons can be produced per hour, and the output per shift can reach 50 tons. It is 20 times more than forging steel balls with an air hammer.

2. The product quality is good. The outer dimensions of the steel balls rolled by the hot rolling heating furnace are uniformly large and small, with the same temperature and no overburning or incomplete burning. Therefore, the hardness after heat treatment is uniform, and the difference between the outer hardness and the inner hardness is small. The product quality is good and stable, with a qualification rate of over 98%.

3. The labor intensity of workers is significantly reduced compared to forging steel balls, and the working environment has been significantly improved. The use of round steel to heat the steel ball production line has completely eliminated the phenomenon of smoke and gas pollution.

4. The steel ball hot rolling furnace produces steel balls with simple operation, high degree of automation, and fewer production processes. Round steel can be heated in the furnace without the need for cutting. No specific professional labor skills are required. New workers can start production after simple training, and they no longer have to worry about substandard product quality, which infinitely stimulates the labor enthusiasm of frontline workers.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 12-08-2023