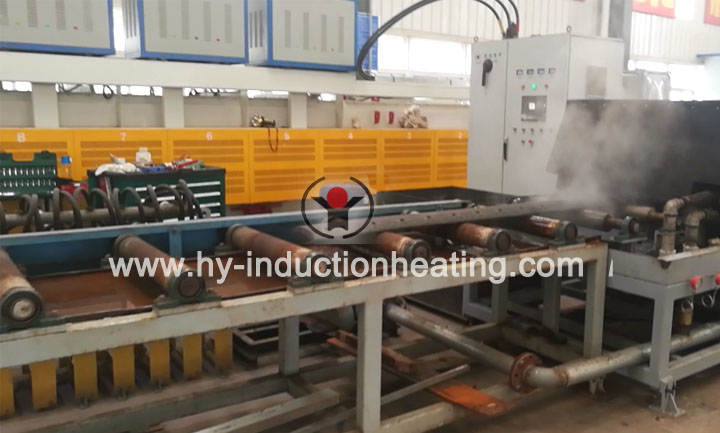

Forever Steel plate induction quenching furnace is an equipment used for metal heat treatment, mainly for enhancing the hardness, wear resistance, and extending the service life of workpieces. The intermediate frequency induction heat treatment quenching equipment launched by Hebei Yuantuo Electromechanical Company, combined with technology and stable performance, helps customers enhance production efficiency and product quality.

Advantages of steel plate induction hardening production line :

Fast heating speed, ensuring uniform heating: using medium frequency induction heating technology, the workpiece heating speed is fast, the temperature control accuracy is high, ensuring that each workpiece can be uniformly heated, avoiding deformation caused by temperature differences. Multi functional adaptation to meet different needs: The equipment supports multiple heating modes and cooling methods, which can be flexibly adjusted according to the material, size, and other characteristics of the customer’s workpiece, ensuring high-precision implementation of different process requirements. Save energy and reduce production costs: The efficient energy utilization and intelligent temperature control system of the equipment not only enhance production efficiency, but also effectively reduce energy consumption, helping enterprises reduce production costs.

Applicable workpieces of the Steel plate induction hardening equipment

Suitable for metal workpieces such as automotive parts, mechanical transmission components, molds, etc. that require high hardness and wear resistance.

Application Fields

Applied to metal workpieces such as pipes, plates, and round steel, especially suitable for the production of parts with high hardness requirements.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 12-17-2024