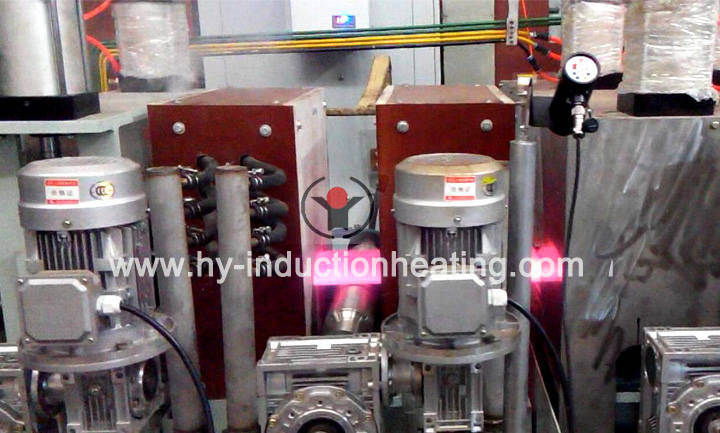

The Intelligent medium frequency induction heating furnace in automatic mechanical industry adopts continuous heating mode, and the load inside the induction ring is more balanced, which overcomes the great change of the actual heating power of the equipment caused by the great change of the load in the whole heating process when the load of a single bar rises from room temperature to 1100 ℃. The actual power of the equipment can be guaranteed to be more than 85 per cent of the rated power value in the whole continuous heating process. steel bar continuous heating is used effectively.

The intermediate frequency induction heating and forging furnace T uses the German original Siemens IGBT power module, and adopts the Fuji rectifier module, and the epoxy resin casting power output transformer is adopted. In that electromagnetic effect principle, the medium-frequency forging furnace rapidly induces a large eddy current in the metal material in the alternating magnetic field, so that the metal material is heated until the electric induction heating device is melted, and the non-metallic material can be penetrated, and the metal material is locally or all rapidly heated. The full-automatic medium-frequency forging furnace is provided with a heating-heat-preservation-cooling three-time setting function, and the heating and heat-preservation power is individually regulated, and the required heating and heat-preservation process can be obtained. And is suitable for batch and repetitive heating places. Up to ten fault-state protection and display, including over-current, over-pressure, underwater, and lack of equal, provide higher reliability and durability. The device is safe and reliable, and the device is safe and reliable, and the device is safe and reliable. 100% full load design, medium-frequency forging furnace can work continuously for 24 hours. Can be matched with the infrared temperature measurement, realize the automatic control of the temperature, improve the heating quality and simplify the operation of the workers.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-17-2019