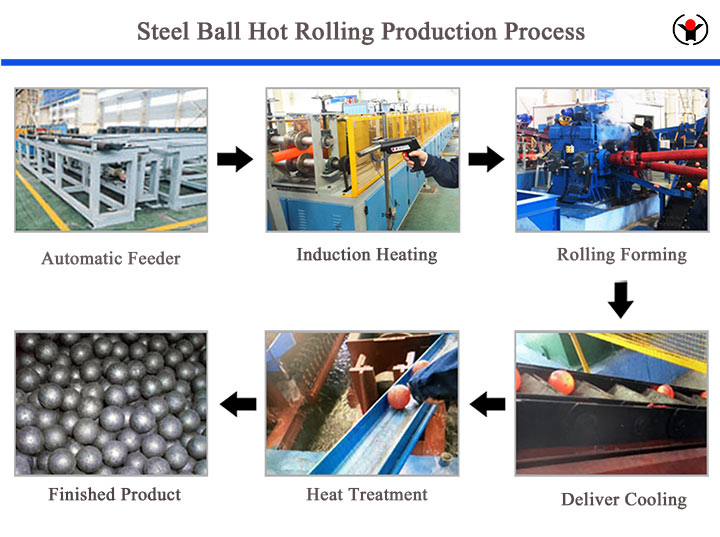

The steel ball hot rolling heating furnace used in the metal hot processing industry can be roughly divided into three types according to their production processes: forged steel balls, rolled steel balls, and rolling forging combination. So how should we choose so many steel ball production equipment?

1. Determine the type of steel ball

After determining which type of steel ball to produce, we can determine the production equipment. The equipment required for steel balls produced by different processes is different!

2. Determine the specifications and output of steel balls

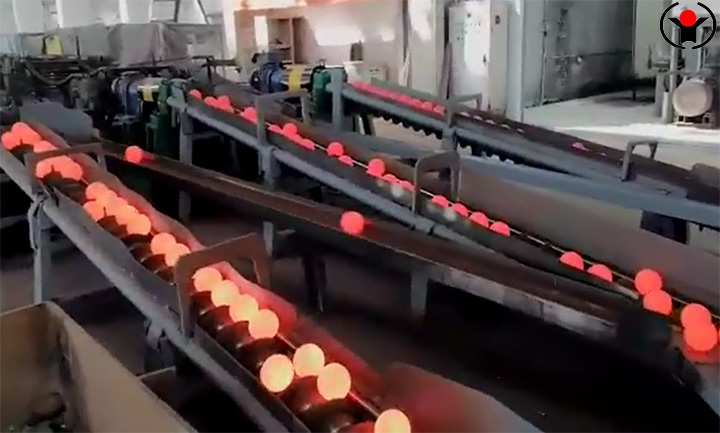

In the steel ball production industry, there is a saying that small steel balls are hot-rolled and large steel balls are forged (i.e. steel balls with a diameter less than 120mm are generally hot-rolled using the steel ball hot rolling process, while steel balls with a diameter greater than 120mm are mostly forged using the ball forging process).

The above is the selection plan for fully automatic Skew rolling steel ball induction machine summarized by Hebei Forever Electromechanical Manufacturer based on years of production practice experience. Forever Electromechanical can customize various plans according to users’ production needs, such as forging steel ball plan, rolling steel ball plan, rolling forging combination plan, etc.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 12-19-2024