Induction hardening and tempering

The purpose of hardening and tempering: After hardening and tempering for steel, the material performance will get great improvement, strength, plasticity and toughness will be improved and will have good comprehensive mechanical properties.

Forever hardening and tempering furnace has got wide application in the wind power industry, engineering machinery and equipment industry, oil industry, railway industry, automobile industry and other industries.

Especially for drill pipe used for sea and land drilling, Forever pipe heat treatment furnace design and production experience has been very rich. Upset heating and temperature difference between the surface can be done evenly heated.We manufactured one set of hardening and tempering furnace system. The hardening temperature: 850 ~ 1000 ℃; tempering temperature: 600 ~ 750 ℃, after quenching and tempering. After testing the workpiece performance fully meet the L80 , P110 and X52 steel standard

The hardening and tempering furnace includes induction heating power, coils, PLC control system, quenching system, tempering system, infusion rack and other major components. Optional accessories are: infrared temperature, frequency cabinet, low with power supply cabinets, cooling systems.

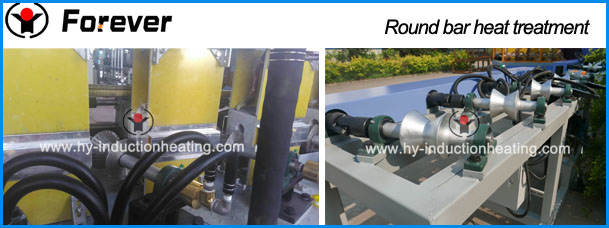

The application of hardening and tempering furnace is also very extensive: Round bar hardening and tempering furnace,casing pipe hardening and tempering furnace,, oil drilling pipe hardening and tempering furnace, steel plate hardening and tempering furnace and so on.

Main features of hardening and tempering furnace PLC control:

● Provide remote console with touch screen or industrial computer system as per users’ requirment.

● Customized man-machine interface, high degree of user-friendly instructions, a person can operate the entire equipment, saving labor and costs.

● All-digital, high-depth adjustable parameters, as long as the worker input the steel garde and specification, the system will run as setting parameters. No need manually record, inquiry and input. With high precision history curve function. we can use U DISK for copy, the data can be permanently saved.

Strict hierarchical management system, the hardening and tempering furnace is equipped with “a key to restore the system”. At present, most of the domestic manufacturers are manually test for different specifications of the steel bar parameters as per experience. But Forever technician has already set the production parameters that the material need to do heat treatment. After starting the system, the operator only need to select the specification part number on the man-machine interface of the operator station, the whole system can run according to the parameters of the specification, so the operation of the system only need to train the operator simply without special professional skills. The program operation can ensure the consistency of product quality than manual operation.

In the operation, the hardening and tempering furnace has complete data monitoring, process records and traceability. The production data such as temperature, current, voltage, water pressure, etc. are displayed on the man-machine interface of the console. The data can be stored in the system for some time to facilitate the user at any time to check, the user can also download the production data to the U disk for long-term preservation.

KGPS IF power supply Features:

● Series resonant design, rectifier fully open, high power factor, resonant component is small.

● T2 copper copper inside the cabinet, sandblasting, passivation treatment, low leakage, anti-oxidation, effectively reduce line losses.

● Intelligent quality system monitoring system: real-time monitoring of power operation status, strong database, flexible storage and view the process parameters.

● One-click quick start: start time 300ms, 100% start success rate.

● Digital circuit Broadband adaptive: Wide frequency range (1 ~ 50kHz), to adapt to a variety of types of workpieces.

● Optical fiber transmission: Using import fiber, fast transmission speed, strong protection, so that the whole stability and reliability greatly improved.

Customer questions:

Q: Does the workpiece need straightening machine after heat treatment?

A: In the field of hardening and tempering, Forever has many success cases, accumulated rich experience, our hardening and tempering furnaces do not need straightening machine.

Q: Other manufacturers need straightening machine, why does your machine not need?

A: In recent years, through our research on the factors of deformation, such as smooth rotation feedjing, workpiece positioning center and achieve multiple power gradient heating, uniform heating, isothermal spray, slow cooling after tempering, delay receiving, all these can make sure the pipe not bend after heat treatment. But for very small pipes, it will have slight deformation (which may be related to the original raw materials and stress).

Contact person: TomWang

Email:yuantuodianlu@163.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Post time: 10-26-2017