The PLC automatic temperature control and induction heating equipment produced by Hebei Yuantuo Mechanical and Electrical equipment Manufacturing Co., Ltd has the functions of recording, querying, printing and so on when the data is realized, and the closed-loop control of power supply power and temperature is automatically adjusted. Real-time monitoring and display of parameters such as heating of induction heating equipment; automatic prediction of faults and alarm; remote centralized control of induction heating equipment; automatic generation of various data reports. In order to make inquiries in future production!

Features of remote electromechanical PLC automatic temperature control induction heating equipment:

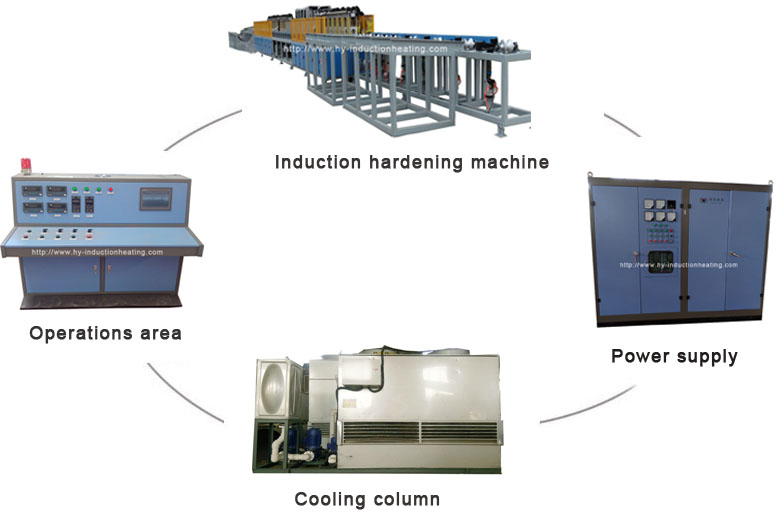

1. Induction heating equipment, medium frequency quenching equipment, induction diathermy furnace, quenched and tempered heat treatment production line adopts unique coil design. The design experience of hundreds of inductors and the advanced induction heating design technology are concentrated. The high quality material is used to realize the best matching of the high efficiency work.

2, folding semi-convenient assembled inductor, the longest new type of energy-saving lining used in China.

3, high efficiency and energy saving of induction heating equipment, low burn loss of billet. Under the condition of no protective atmosphere, most of the blank precision molding requirements can be met because of the next process need to be briefly shut down,

4, as long as pressing the control of the heat preservation button, the billet can automatically heat preservation.

5, high heating speed, high production efficiency, the hardness performance of the treated workpiece is consistent.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-26-2019