The cost-effective induction heating equipment for prestressed steel bar is Zhixuan YUANTUO Electromechanical. The induction heating equipment of prestressed steel bar adopts IGBT induction heating power supply control, which has similar performance and similar price with silicon controlled rectifier control power supply. However, the induction heating equipment for prestressed steel bar has obvious power saving effect and reliable quality. According to the actual process requirements of users, suitable Induction heating machine and induction heating device are customized Heat treatment equipment, induction quenching equipment, quenching and tempering heat treatment production line, etc. Welcome to inquire!

Main technical parameters of induction heating equipment for prestressed steel bar:

1. Power supply system: igbt500kw-igbt2000kw.

2. Hourly output: 2.0-16 tons.

3. Inductor design: variable turn pitch, temperature gradient design, more efficient.

4. Elastic adjustable press roll: the round steel bars of different diameters can be fed at a constant speed. The roller table and pressure roller between furnace bodies are made of 304 non-magnetic stainless steel and water-cooled.

5. Infrared temperature measurement: the infrared temperature measuring device is set at the discharge end to make the temperature of steel bar consistent before entering the rolling mill.

6. Energy conversion of hot rolling ribbed steel bar equipment: heating diameter 25 ~ diameter 36 ~ 1000 ℃, power consumption 260 ~ 280 degrees.

7. According to the needs of users, remote operation platform with touch screen or industrial computer system is provided.

8. Specially customized man-machine interface, highly humanized operation instructions.

9. All digital, high depth adjustable parameters, let you control the equipment handy.

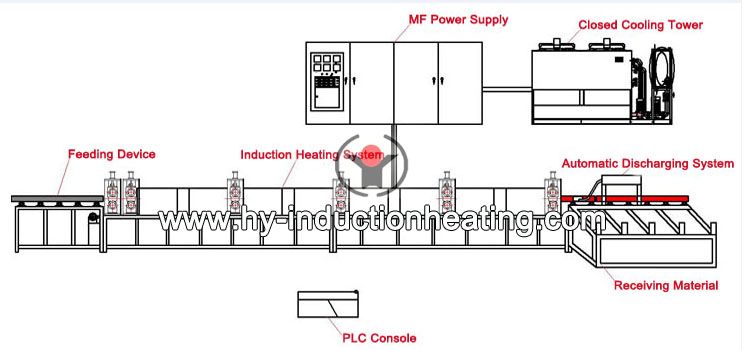

Composition of induction heating equipment for prestressed steel bar:

1. Induction heating power supply

2. Induction furnace body

3. Compensation capacitor furnace cabinet (including stainless steel pipe, capacitor cabinet, conveying roller and press roll)

4. PLC control system (including control technology and signal isolation control board)

5. Connecting wire (power supply to furnace body)

6. Infrared temperature measurement system

7. Storage rack and automatic feeding and conveying system

YUANTUO Electromechanical is a professional induction heating equipment manufacturer. With many years of production experience in steel rolling heating equipment and induction heating equipment, it has rich production experience and successful cases in the field of prestressed steel bar induction preheating equipment. If you have the demand in this respect, you can dial the station telephone directly to provide you with the quotation and scheme of induction heating equipment and induction heat treatment equipment for free .

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 07-13-2020