Executive standards for pipe heat treatment and quenching equipment:

1. GB/T10067.1-2005 “Basic Technical Conditions for Electric Heating Equipment – General Part”

2. GB/T10066.1-2004 “Test Methods for Electric Heating Equipment – General Part”

3. GB/T10067.3-2005 “Basic Technical Conditions for Electric Heating Equipment – Induction Electric Heating Equipment”

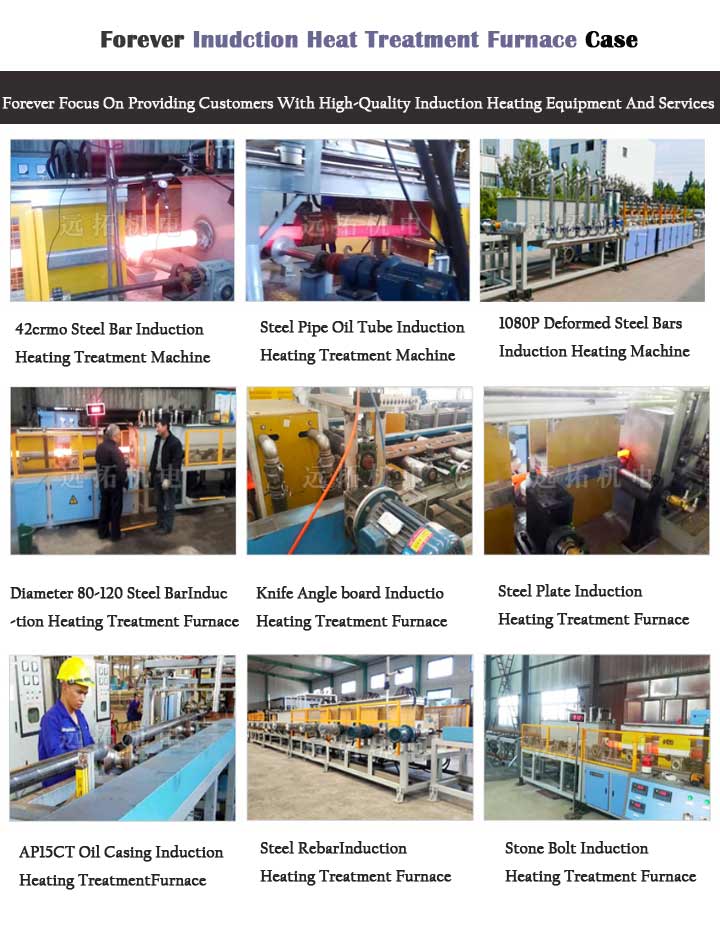

bar pipe heat treatment furnace

induction hardening furnace is controlled by a series resonant intermediate frequency power supply, and its control system also has the unique constant power/constant angle mode selection function of Yuantuo. When relatively high power is needed in the low frequency range or other areas, choosing constant power mode can continue to increase the intermediate frequency voltage and DC current after the DC voltage is fully output, and automatically adjust the matching of load positive reactance. To achieve relatively constant power output, achieving the goal of saving time, electricity, and improving the power factor on the grid side. When precise control of the inverter leading angle is needed in the high-frequency range or other areas, the constant angle mode can be selected to automatically adjust the inverter leading angle during operation, ensuring stable operation of the pipe heat treatment quenching equipment under various harsh conditions such as rapid impedance changes and high working frequency, without causing shutdown or device damage due to commutation failure.Pipe induction quenching furnace

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 08-25-2023