Does the Billet induction heating furnace consume electricity? This is a concern for many users who want to choose sufficient heating equipment for steel billets. The amount of electricity consumed by the equipment is closely related to the temperature, size, and production efficiency of the heated workpiece.

steel billet heating furnace is mainly used for heating before cold billet rolling and for heating and compensating continuous casting steel billets. Due to the relatively high power of large-scale cold billet heating equipment, the transformer capacity required for power supply will be large, and the energy-saving effect is not significant. When used for heating steel billets, as only surface heating can meet the rolling requirements, the energy-saving effect is very obvious. Therefore, induction heating furnaces for steel billets are mostly used for heating steel billets.

Due to the different temperatures raised, the power consumption per ton during the heating of steel billets generally ranges from 15 to 50 degrees Celsius.

The entire set of steel billet induction heating furnace mainly consists of a high-power fully digital variable frequency power supply, induction heating coils, variable frequency feeding system, and cooling circulation system.

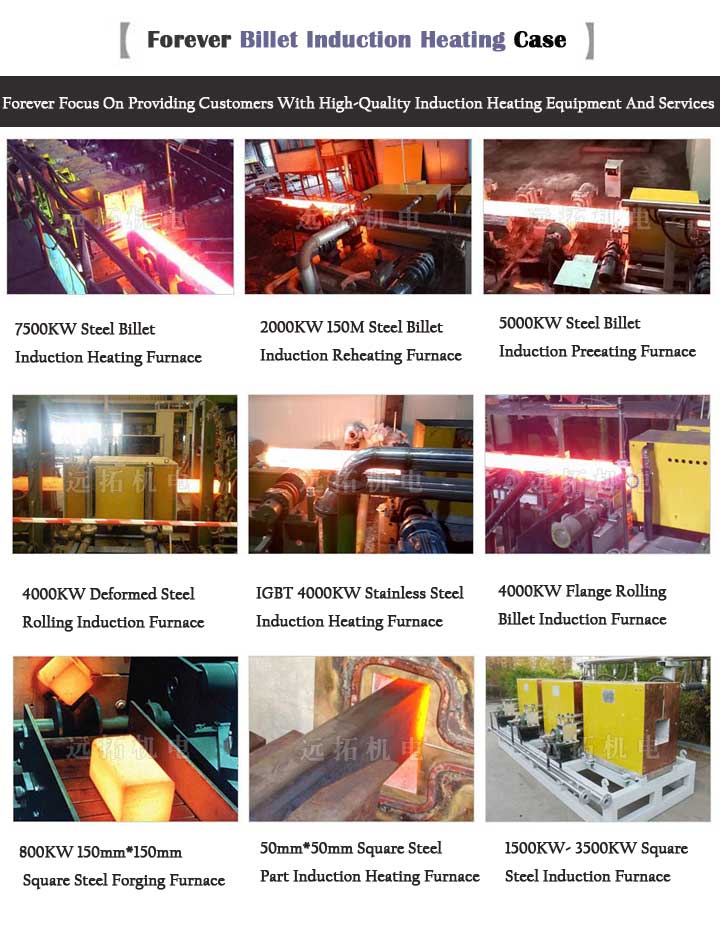

Forever Electromechanical Steel Billet Induction Heating Furnace adopts electromagnetic induction heating technology, infrared temperature measurement feedback, and remote intelligent control system. It has the characteristics of fast heating speed, less oxidation and decarburization, high temperature control accuracy, real-time monitoring of production situation, and easy digital automatic operation.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China;Glad to be your business partner in induction heating field.

Post time: 04-24-2024