Reasonable operation of continuous hardening and tempering furnace to prevent cracking

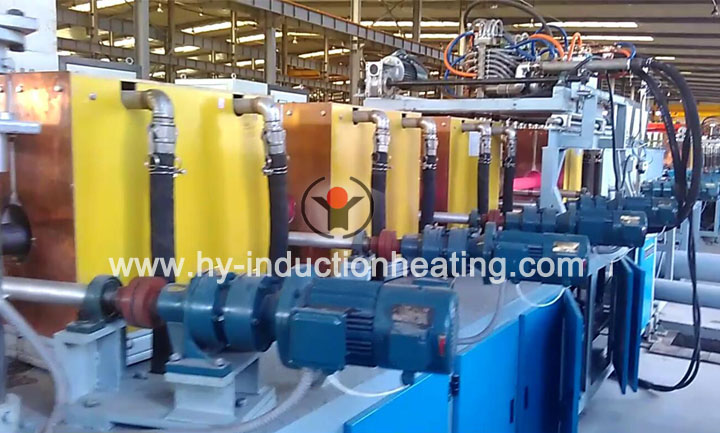

Forever is a professional manufacturer of automatic induction billet heater and continuous hardening and tempering furnace. We are aimed at providing customers with automatic heating solutions and induction heating equipment based on all-digital induction heating technology. Applications include wind power, automobiles, petroleum, railway transportation, mining Other industries and fields.

In the process of heat treatment using continuous hardening and tempering furnace, it’s common to see that bad operations will result in the workpiece crack or deformation. Especially when the workpiece shape is complex, there is much quenching stress inside the workpiece due to some wrong quenching process or other factors, which result in workpiece crack. In order to strengthen the induction heating quenching heat treatment cracking and prevention of problems, to improve product quality and economic benefits has great significance;

Today, we will tell you about how to prevent workpiece crack after hardening and tempering heat treatment.

1.Improve the parameters of the process performance;

2.Control the heating temperature to avoid too high temperature;

3.Using the method of uniform cooling;

4.Control the water spray pressure and flow;

5.Using natural tempering or timely tempering;

6.Increase the gap between the induction heater and the workpiece;

7.Pay attention to the workpiece surface temperature uniformity;

Controlling, reducing and preventing hardening heat treatment deformation and cracking are problems that people attach great importance to in production. Experience from many factories proves that to achieve the above purpose, effective measures should be taken not only in the heat treatment process and the operation of continuous hardening and tempering furnace.We should also pay attention to the other production procedures.

Contact person: Tom Wang

Email:yuantuodianlu@163.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Post time: 01-16-2018