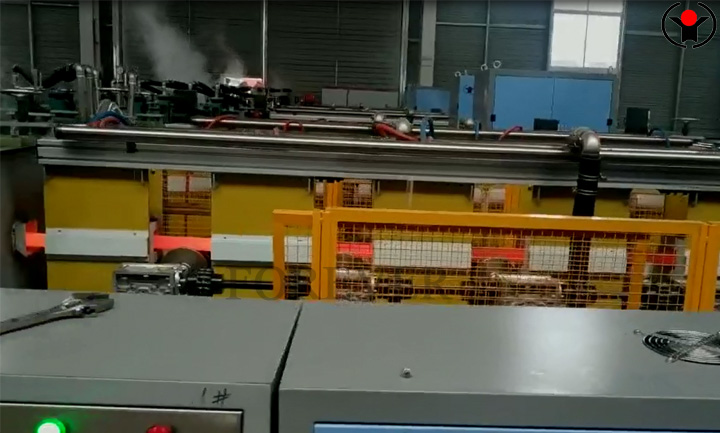

The 48mm x 48mm square pipe induction hardening equipment is designed for quenching heat treatment of workpieces such as square tubes, rectangular tubes, and automotive anti-collision beam tubes. It is suitable for workpieces with a cross-section of 48mmx48mm and a pipe wall thickness between 1mm and 2mm, with a length of 2.5m to 7m.

This processing line adopts KGPS200KW power equipment, with a production speed of 2m to 5m per minute, which can meet the needs of large-scale square tube heat treatment processing. During the quenching and heating process, the square pipe induction hardening line can ensure that the core surface temperature difference and front and rear temperature difference of the steel pipe are controlled within<± 10 degrees, and can achieve uniform heating of the workpiece. By precisely controlling the quenching heating temperature, it is possible to ensure the desired quenching effect for customers.

The square steel pipe induction heating equipment includes core components such as a medium frequency power supply cabinet, PLC operating platform, induction heating furnace body cabinet, and spray quenching box, achieving automatic control of the workpiece quenching process. The control system of the entire square steel induction heat treatment production line adopts a PLC system, which can flexibly adjust the operating process and parameters according to needs. The design of the furnace body focuses on stability and durability, and uses water-cooled rollers and 304 stainless steel material to ensure the long-term stable operation of the equipment.

Overseas manager: Tom Wang Email:tom@foreverfurnace.com Phone: 0086-13303078975(whatsapp, wechat,line) Specialist of induction heat treatment furnace in China;Glad to be your business partner in induction heating field.

Overseas manager: Tom Wang Email:tom@foreverfurnace.com Phone: 0086-13303078975(whatsapp, wechat,line) Specialist of induction heat treatment furnace in China;Glad to be your business partner in induction heating field.

Post time: 05-07-2024