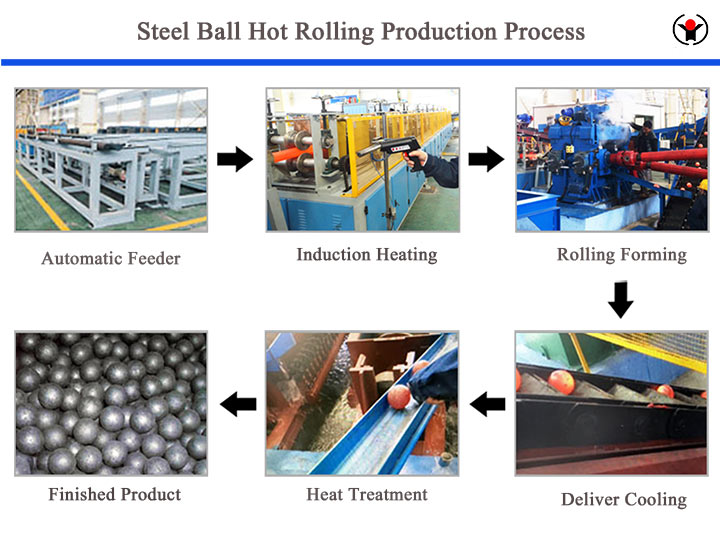

The steel ball hot rolling induction heating production line is a type of steel ball production equipment.

This steel ball hot rolling production line mainly includes induction heating equipment, rolling mills, and related auxiliary equipment.

The working principle and characteristics of the induction heating production line for hot rolling steel balls:

1. Induction heating equipment: The induction heating equipment in the steel ball hot rolling furnace adopts the principle of electromagnetic induction, converting electrical energy into thermal energy, and achieving heating of round steel. Through reasonable induction coil design and power control, the round steel can be quickly and uniformly heated to the required processing temperature.

2. Rolling mill: The heated round steel material is processed by the rolling mill. The rolling mill can continuously roll, cool, and adjust the diameter of round steel to process it into steel balls. A rolling mill usually includes a series of rollers and seats, and through appropriate adjustment and control, the forming of steel balls, diameter accuracy control, and surface quality requirements can be achieved.

3. Auxiliary equipment: Steel ball hot rolling induction heating production lines are usually equipped with some auxiliary equipment, including cooling systems, conveying systems, and quality inspection systems. The cooling system is used for rapid cooling of heated materials, controlling the structure and hardness of steel balls. The conveying system is responsible for continuously conveying the processed steel balls to the next process or for storage. The quality inspection system is used to detect indicators such as the diameter, surface quality, and hardness of steel balls, ensuring that the product meets the requirements.

4. Automation control: The steel ball forging production line can achieve automation control and monitoring of the entire production process through an automation control system. Through sensors, temperature measuring instruments, and advanced control systems, real-time monitoring and adjustment of heating, rolling, and quality inspection processes can be achieved, improving production efficiency and product quality.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China;Glad to be your business partner in induction heating field.

Post time: 05-30-2024