In the metal hot processing industry, the steel bar heating furnace is a quite mature heating equipment, especially the heating before forging. The steel bar heating furnace is indispensable. The steel bar heating furnace is mainly medium frequency heating furnace in forging heating. With its fast heating speed, convenient operation, energy conservation and environmental protection, it has won a lot of reputation for the medium frequency heating furnace. Next, let’s go to the steel bar heating furnace to learn about it!

1、 Background of steel bar heating furnace:

The traditional heating method of steel bar heating furnace is flame heating, which heats steel bar by burning heavy oil, natural gas and other media. It has the disadvantages of poor heating environment, long heating time and high cost of flue gas desulfurization. With the progress of science and technology and the maturity of medium frequency components, the steel bar heating furnace has gradually transited to the era of medium frequency heating furnace. Flame heating is only used for free forging heating, while the heating of forged steel bars has been occupied by medium frequency heating furnaces. The steel bar medium frequency heating furnace is an indispensable induction heating equipment for heating before forging.

2、 Composition of steel bar heating furnace:

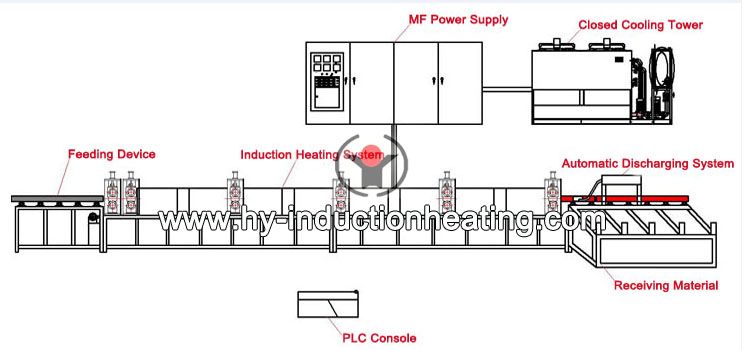

The steel bar heating furnace is mainly composed of medium frequency power supply, inductor, beat controller, inductor furnace frame, cooling system, automatic feeding system, infrared temperature measurement system, conveying system, discharging system and control system.

3、 Advantages of steel bar induction heating furnace:

1. High heating temperature and non-contact heating;

2. Fast heating speed – less oxide layer on the surface of the workpiece to be heated and small deformation of the workpiece;

3. Easy temperature control – stable product quality;

4. It can quickly heat the secondary deformation workpiece at any time to meet the process requirements.

5. High heating efficiency – energy saving;

6. It can be locally heated – good product quality and energy saving;

7. The operation is simple and easy to realize automatic control – labor saving and labor saving;

8. Small land occupation – high production efficiency;

9. The environment is good – there is almost no heat, noise, dust, etc

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Post time: 09-22-2022