【 Scope of Application 】 20mm to 120mm

【 Main Application 】 Suitable for steel bars, low-carbon alloy steel, wind turbine bolts, lead screws, and hydraulic cylinder rods quenching and tempering heat treatment.

【 Energy Conversion 】 Adopting the method of hot quenching followed by high-temperature tempering, with a power consumption of 420-480 kWh per ton.

Characteristics of Steel bar quenching tempering equipment :

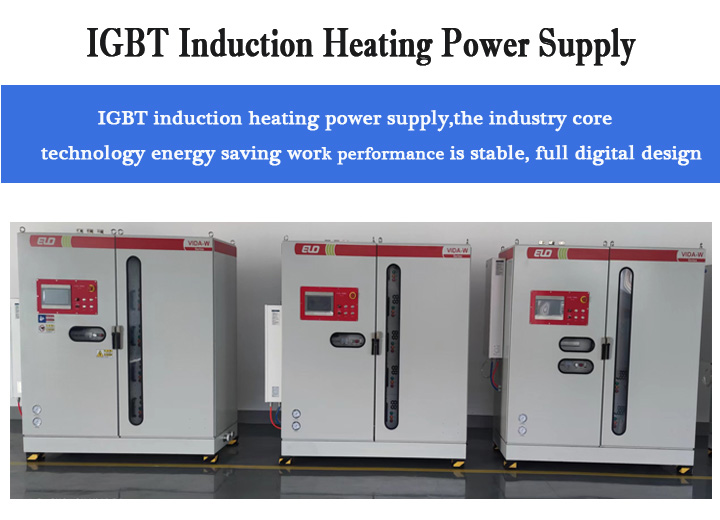

1. The steel bar quenching and tempering heat treatment furnace is controlled by a resonant intermediate frequency power supply, which can achieve high power.

2. Conveyor roller conveyor: The axis of the roller conveyor forms an angle of 18-21 ° with the axis of the workpiece, allowing the workpiece to self rotate while moving at a constant speed, resulting in more uniform heating. The roller conveyor between the furnace bodies is made of 304 non-magnetic stainless steel and water-cooled. The roller conveyor in other parts is made of 45 steel and has a surface fire.

3. steel bar induction heat treatment machine roller grouping: the feeding group, sensor group, and discharge group are independently controlled, which is conducive to continuous heating without creating gaps between workpieces.

4. Temperature closed-loop system: Both quenching and tempering are carried out using American Raytheon infrared thermometers and a closed-loop control system composed of German Siemens S7, with accurate temperature control and more uniform heating.

5. The steel bar induction hardening and tempering furnace is controlled by an industrial computer system, which displays the real-time status of the working parameters, and has functions such as workpiece parameter memory, storage, printing, fault display, and alarm.

6. After quenching and tempering heat treatment, the grinding rod has no cracks and a pass rate of up to 99% on the head.

7. Forever’s independent intellectual property rights for parallel and series resonant intelligent control technology, with full touch screen digital operation, rank among the top in China and internationally.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 12-16-2024