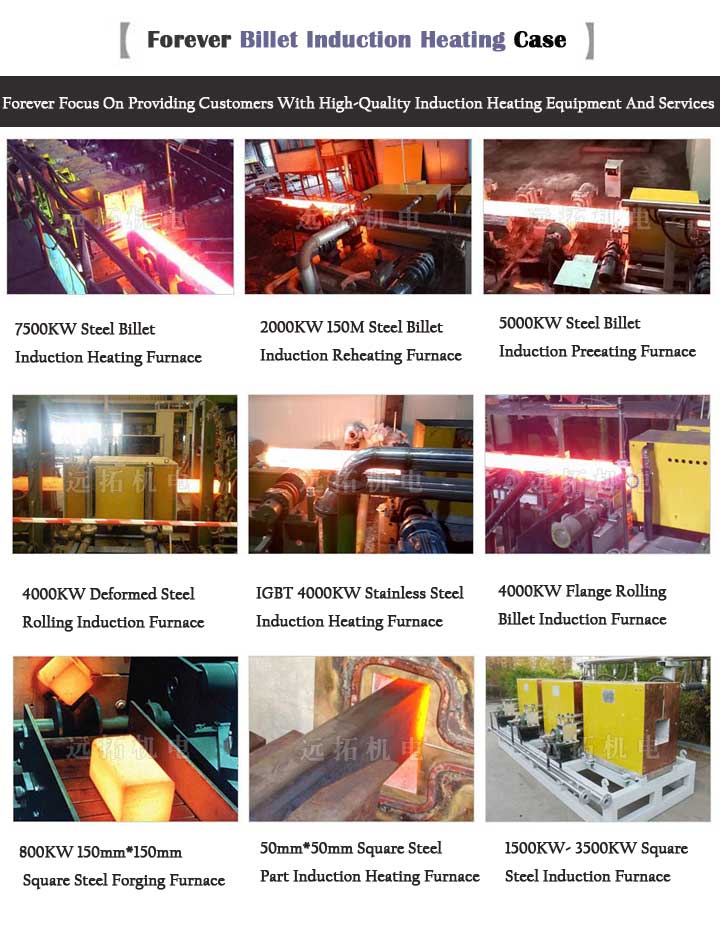

Hebei Forever Electromechanical Professional provides steel billet induction reheating furnaces, PLC fully automatic intelligent control, closed-loop temperature control for steel billet heating furnaces, uniform heating, no overburning, no deformation, no cracks, quality assurance, and free technical solutions and quotations for steel billet heating furnaces and induction heating equipment for users.

【 Feeding System 】 Each axis is driven by an independent motor reducer, with multi axis drive and single frequency converter control to ensure synchronous operation of multiple axes.

【 Guide System】 Adopts 304 non-magnetic stainless steel guide wheels and maintains moderate elasticity in the axial direction of the guide wheels to adapt to the bending within the allowable range of the steel billet.

Technical renovation project for replacing gas and natural gas heating furnaces with online Billet induction heating machine :

The traditional steel rolling process involves cooling the steel billets produced by steelmaking, transporting them to the rolling mill, and then heating them in a heating furnace before rolling them into steel. This process has two shortcomings:

1. After being pulled out of the steelmaking and continuous casting machine, the steel billet has a temperature of 700-900 ℃ on the cooling bed, and the latent heat of the steel billet has not been effectively utilized.

2. After being heated by a heating furnace, the surface of the steel billet experiences an oxidation loss of about 1.5%.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China;Glad to be your business partner in induction heating field.

Post time: 04-10-2024