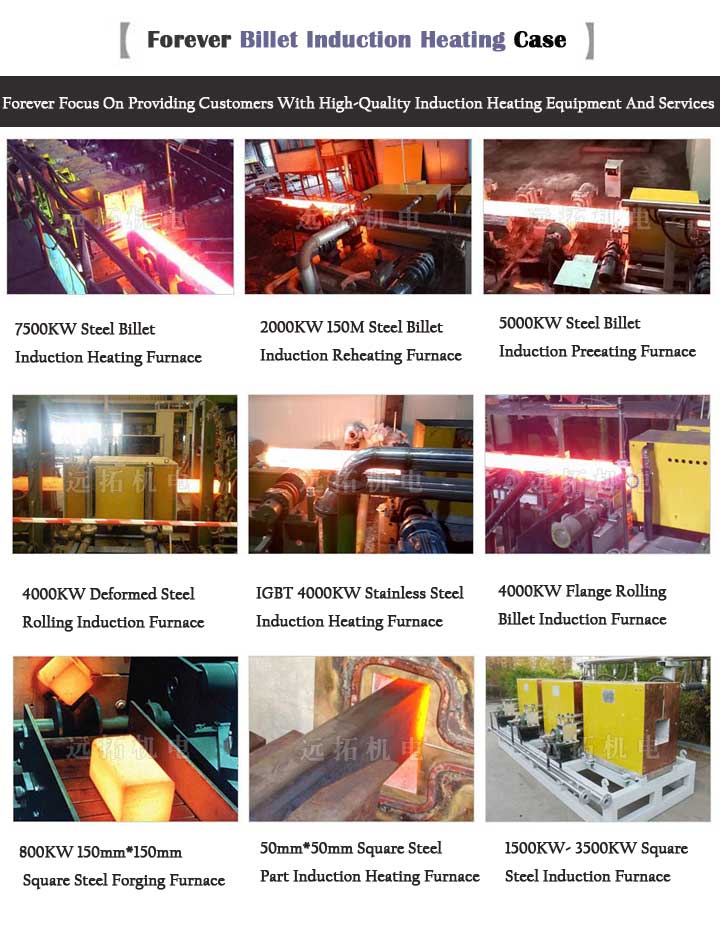

steel billet induction heating furnace is mainly used for heating heat-resistant sliders, cushion blocks, continuous casting billets, tube billets, square steel, square billets, ground bar steel, square steel billets, round billets, stainless steel billets, seamless steel pipe billets, rectangular billets, and other steel billets. The equipment uses a solid-state power supply to efficiently provide magnetic fields to the coils, providing you with high-quality and efficient technology and heating efficiency, so that the surface temperature of square billets, slab billets, round billets, tube billets and other workpieces meets the ideal temperature requirements for forming, forging, and rolling. Improve stamping production efficiency, stability, safety, and reduce labor intensity.

steel billet induction reheating furnace, also known as steel billet temperature rise and compensation heating production line

Working principle: Steel billet heating is achieved through electromagnetic induction heating technology. The control system is programmed and controlled by touch screen and PLC program. The feeding speed and heating temperature settings can be directly inputted on the touch screen.

Selection instructions: Equipped with temperature increase and compensation function; Heat resistant sliders, spacer blocks, continuous casting billets, pipe billets, square steel, square billets, ground bar steel, square steel billets, round billets, stainless steel billets, seamless steel pipe billets, rectangular billets, etc. with a cross-sectional area of 60mm-160mm and a length of 3000mm-1200mm shall be heated before rolling.

Suitable for: steel bar and strip rolling production in steel furnaces.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China;Glad to be your business partner in induction heating field.

Post time: 04-18-2024