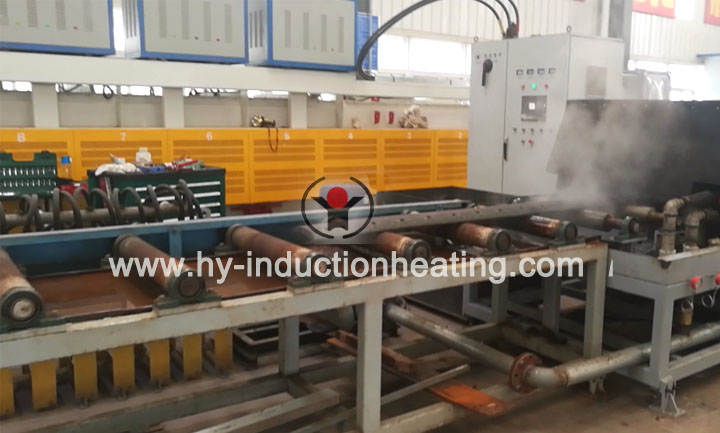

Forever Steel plate heat treatment furnace is an automated device specifically designed for the heat treatment of steel plate materials, produced by Hebei Forever Electromechanical Equipment Manufacturing Co., Ltd. This device collaborates with induction heating, precise cooling, and automatic control systems to efficiently and uniformly temper steel plates, effectively meeting the quenching and tempering needs of various industrial fields for steel plate hardness, toughness, and surface quality.

Steel plate heat treatment furnace debugging steps

Air pressure regulation: The air pressure of the Forever steel plate quenching and tempering equipment usually needs to be maintained at around 0.5 MPa. Air pressure regulation ensures that the equipment has a stable power source during operation, avoiding the impact of insufficient air pressure on heating or cooling effects.

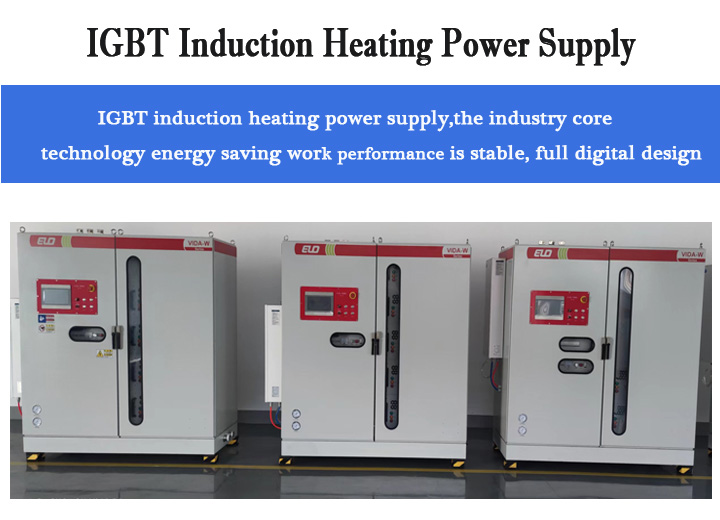

Temperature and power calibration: Before using the equipment, temperature and power calibration should be performed to ensure the accuracy of the heating system. By detecting the temperature control module and heating power, ensure that the heating process of the equipment meets the set standards.

Cooling system inspection: During debugging, it is necessary to check the flow rate, pressure, and spray uniformity of the cooling system of Hebei Forever Electromechanical Equipment to ensure the stability of the cooling effect. The normal operation of the cooling system provides a guarantee for the final effect of the steel plate induction hardening and tempering furnace conditioning process.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 11-20-2024