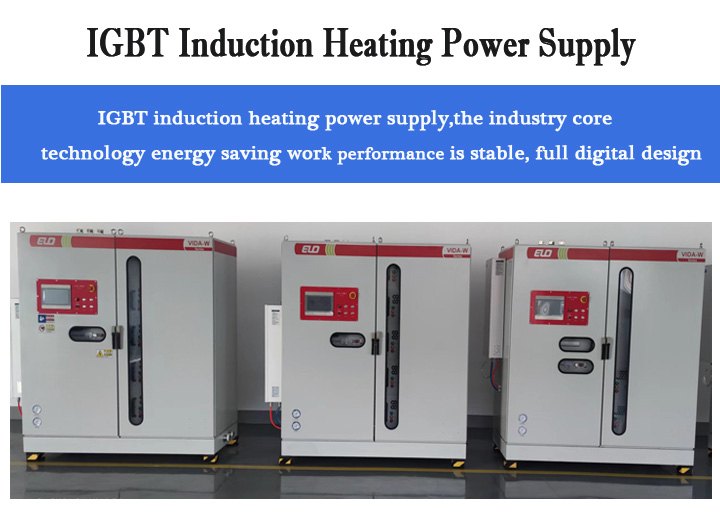

Forever’s independent intellectual property rights for parallel and series resonant intelligent control technology, with full touch screen digital operation, are leading domestically and internationally.

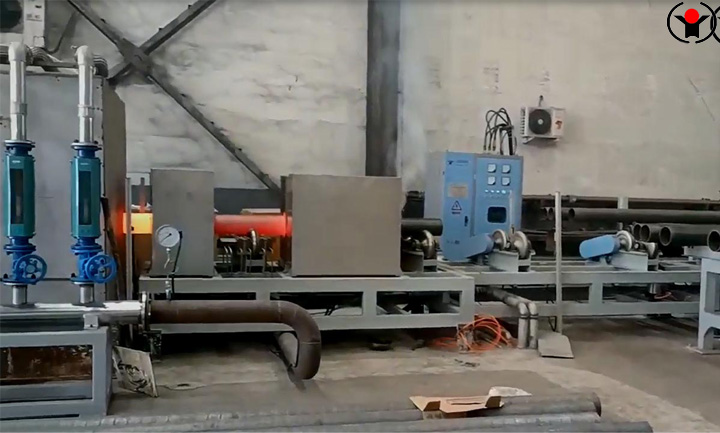

Main advantages of steel pipe induction heating furnace :

1. Efficient and rapid heating

The steel pipe heating furnace utilizes intermediate frequency induction heating technology to heat the steel pipe to the desired temperature in a very short period of time. Induction heating directly heats the inside of steel pipes through electromagnetic induction, without relying on external heat conduction like traditional furnaces, greatly reducing heating time and improving production efficiency,

2. High uniformity of heating

Uniform heating of inner and outer walls: The Inducntion heating furnace for pipe uses induction lines to evenly distribute electromagnetic energy on the inner and outer walls of the steel pipe, ensuring consistent temperature distribution during the heating process.

Reduce oxidation and decarburization: Due to the short heating time and independence from combustion processes, the phenomenon of oxidation and decarburization on the surface of steel pipes is significantly reduced, thereby maintaining higher surface quality.

3. Precise temperature control, stable quality

Precise temperature control system: The steel pipe heating furnace is equipped with a closed-loop temperature control system, which can monitor and adjust the heating temperature of the steel pipe in real time. The temperature control accuracy can usually be maintained within+5 ℃.

Multi process adaptability: The steel pipe induction heating equipment can flexibly adjust parameters such as temperature, power, heating time, etc. according to different steel specifications, materials, and processing requirements, and is suitable for various heat treatment and processing processes (such as bending pipes, welding preheating, etc.).

4. High automation and intelligence

Modern steel pipe heating furnaces are usually equipped with automated production lines and intelligent control systems, which have functions such as automatic feeding, heating, and discharging. Through PLC (Programmable Logic Controller) and HMI (Human Machine Interface), operators can easily set and monitor the heating process, reducing manual operations and improving production efficiency.

5. Energy conservation and environmental protection

High energy efficiency ratio: The electric energy utilization efficiency of medium frequency induction heating is very high, without intermediate heat transfer medium, with low energy loss and reduced operating costs.

Pollution free heating process: There is no open flame or smoke emission during the heating process, avoiding the emission of exhaust gas and pollutants generated during the combustion process.

6. Diversified applications

Steel pipe heating furnaces are widely used in various industrial fields, including:

Heating of steel pipe bends: Suitable for preheating before bending and forming pipes to ensure the plasticity of the pipe during the bending process.

Preheating before welding: used for preheating large diameter steel pipes before welding to improve welding quality

Steel pipe heat treatment: Annealing, normalizing, quenching and other heat treatment processes are used to improve the microstructure and mechanical properties of steel pipes by controlling different heating and cooling rates.

Anti corrosion coating heating: During pipeline anti-corrosion treatment, the surface of the steel pipe needs to be heated to facilitate better adhesion of the coating material and enhance the anti-corrosion effect.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 10-17-2024