Where are the advantages of bar continuous hardening and tempering furnace?

YuanTuo is a professional manufacturer of automatic continuous hardening and tempering furnace, providing customers with automatic heating solutions and induction heating equipment based on all-digital induction heating technology. Applications include wind power, automobiles, petroleum, railway transportation, mining and other industries and fields.

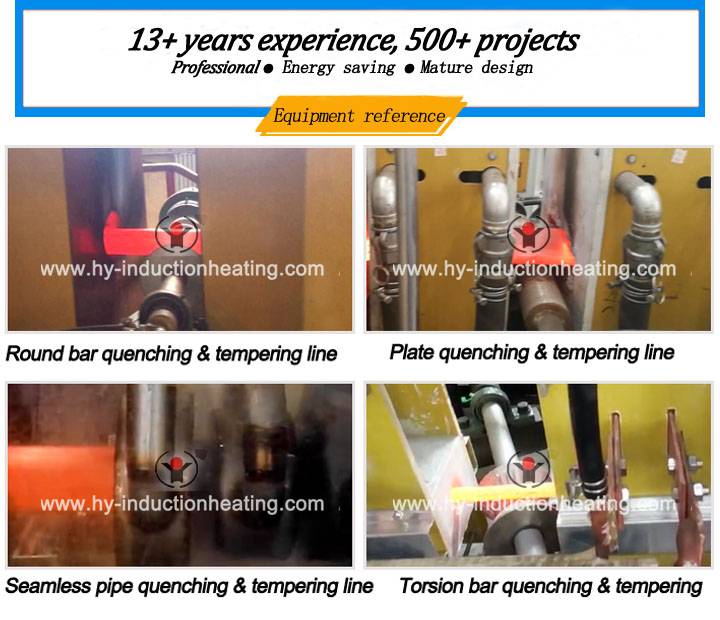

Round bar continuous hardening and tempering furnace is widely used in round bar surface heat treatment and through heat treatment, which can be used for quenching, tempering, normalizing, quenching and diathermy. It is more cost-effective to mechanize large-scale production, users can control unmanned operations through computer control.

First, what are the advantages of bar continuous hardening and tempering furnace?

1. Shorten the production cycle and improve working conditions.

2.Improve the level of production organization and improve product quality.

3.Compared with the flame heating furnace,continuous hardening and tempering furnace can save more than 2% of the material, while increasing the service life of the forging die.

4.Induction heating will not produce smoke, which can clean the workshop environment.

5.Heating time is short, efficiency is high, induction heating efficiency can be up to 60% to 70%.

Second, what kind of application can hardening and tempering furnace be used?

1. Oil drill pipe continuous hardening and tempering furnace

It is mainly used for heat treatment of petroleum pipelines (oil drilling rods, drill collars), pipeline heating before coating.

2. Long axis medium frequency continuous hardening and tempering equipment

Hardening and tempering used for larger diameter shafts (workpiece diameter 30 to 500).

3.Bar quenching heat treatment production line

Mainly used for continuous hardening and tempering of automotive torsion bar, rack thick (rods) and a variety of shaft blank.

4.Prestressed steel rebars heat treatment equipment

5.Plate continuous heat treatment production line

The production line adopts PLC centralized control, which is safe and reliable.

With the development of industry and the improvement of hardening and tempering technology, induction heating equipment will bring economic benefits and a good working environment.

Contact person: Tom Wang

Email:yuantuodianlu@163.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of Induction billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Post time: 03-09-2018