Drill collar induction heat treatment furnace

Features:

| Material |

AISI4145H |

| Diameter |

2 3/8″-6 5/8″ |

| Process | Quenching, tempering, annealing |

Product Detail

Application Video

Product Tags

A Drill Collar is a tubular piece of a drill string which provides weight on the bit for the purpose of drilling. So drill collar performance is good or not is very important in the oil industry. The drill collar can be used only after heat treatment. Forever Drill collar induction heat treatment machine can help you finish this work.

Site case for Drill collar heat treatment furnace

| Product name | drill collar induction heat treatment furnace |

| Brand | Forever |

| Material |

AISI4145H |

| Diameter |

2 3/8″-6 5/8″ |

| Process | Quenching, tempering, annealing |

| Quenching temperature | 920-930℃ |

| Power required | 100-5000KW |

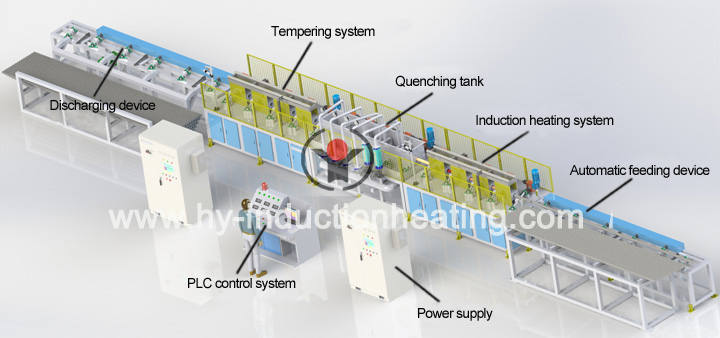

Automatic feeding material → frequency conversion roller conveyor → rotary heating → rotating water →rotating tempering heating → variable frequency roller output → receipt.

The entire process is automatically completed by the PLC, and recording the parameters of the production process: power supply status, temperature, and production and other data.

Why choose Forever Heat treatment furnace for drill collar?

1.Equipment protection is complete

The pipe heat treatment furnace alarm functions for water temperature, water pressure, lack of phase, overvoltage, overcurrent, current limit, start overcurrent, constant current, so that the device starts smooth, reliable and fast;

2.Rapid heating speed, less oxidation decarbonization

As the principle of IF heat treatment furnace is electromagnetic induction, the heat will generate inside the workpiece, so there is very little oxidation skin.

3.Automatic loading & unloading

Can achieve automatic unmanned operation, improve labor productivity;

4.Low energy consumption, pollution-free, high efficiency

Compared with other heating methods, effectively reduce the energy consumption, improve labor productivity, pollution-free;

5.Uniform heating, high temperature control accuracy.

Uniform heating is the key to make sure the pipe microstructure get uniform transformation. So we set two sets of double coulor infrared thermometer to monitor the heating temperature. Once the temperature is out of the setting value, the system will adjust it by changing the power.

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)