Intermediate frequency diathermy equipment

Features:

1.Induction heating power: DSP+IGBT Intelligent induction heating power,saving energy 10%-15% ,no pollution.

2.Process monitoring screen and Data logging and Archiving

3.Application:Heat Treatment and Heating for many kinds of metal parts,no matter the part size.

Product Detail

Application Video

Product Tags

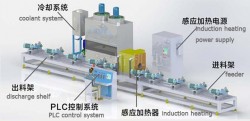

Intermediate frequency diathermy equipment for bar through heating

Intermediate frequency diathermy equipment is mainly composed of six major components,such as feeding mechanism, feeding mechanism, frequency power supply (depending on the power set), cooling system, temperature control system and insulation system .The diathermy machine were designed according to user requirements and manufacture heating process, which consists of bed , part of the vibration plate, feeding device, transmission device, discharging device, a resonant tank circuit, the cooling device, temperature measurement and control system and electrical control system.wherein a part of the user can choose according to needs.In thermal process , the heated workpiece were through in the inductor.

First, application of the intermediate frequency diathermy equipment:

A diathermy machine tool in combination with high or intermediate frequency power supply to realize the heating process. It was used to forging, forming, welding, annealing and heat treating process of bar, pipe, wire, plate and all kinds of metal parts.

Second, the main technical parameters

Output Power: 20 ~ 3000kW

Output frequency: 0.5 ~ 100kHz

Max temperature: 1250 ℃ (black metal) 2500 ℃ (refractory metal)

Output voltage: 20 ~ 2000V

Heated workpiece material: steel, iron, copper, aluminum, stainless steel, tungsten, molybdenum, tantalum, niobium, etc.

Temperature measurement : the far-infrared temperature measurement

Third, the common intermediate frequency diathermy equipment type:

1, Rod, pipe segment diathermy equipment: segment-shaped rods, tubes or forging material stamping before diathermy;

2, Wire diathermy equipment: linear material or disc-shaped wire diathermy;

3, Sheet diathermy equipment: automotive sheet spring steel and other materials through plate-shaped heat;

4, Shaped parts and local diathermy equipment: shaped parts for total or partial diathermy;

5, Wire diathermy equipment: heat the whole or in part of the materials in the continuous production line,such as PC steel Induction heat treatment production line, seamless steel pipe rolling production line, seam steel pipe production line, pipe production line, cap sealing production line .

More information about induction heating equipment,please to visit our website: http://www.hy-inductionheating.com.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.