Quenching and tempering furnace for plate

Features:

| Material | 29Mn5, 25MnCr, 25CrMnMo, 25MnV |

| Plate thickness | ø30-100 mm |

| Control system | PLC control |

| Process | Quenching, tempering |

Product Detail

Application Video

Product Tags

Controlled by Siemens PLC, Forever quenching and tempering furnace for plate only need 1 work to operate the whole quenching and tempering system. Please tell us your plate width, thickness, length and capacity, then we will provide solutions for quenching and tempering furnace for plate.

Site case for Quenching and tempering furnace for plate

| Product name | Quenching and tempering furnace for plate |

| Brand | Forever |

| Material | 29Mn5, 25MnCr, 25CrMnMo, 25MnV |

| Plate thickness | ø30-100 mm |

| Control system | PLC control |

| Process | Quenching, tempering |

| Quenching temperature | 920-930℃ |

| Tempering temperature | 680-700℃ |

| Power required | 100-5000KW |

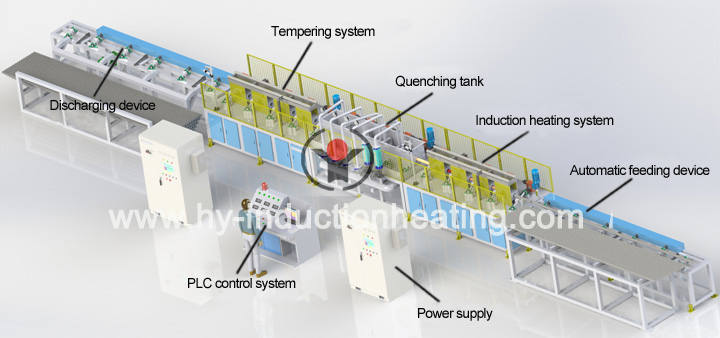

Quenching and tempering furnace for plate composition

● Feeding device

● Transportation roller table

● Induction heating system for quenching

● Spraying cooling system

● Induction heating system for tempering

● Automatic turning material device

● Water circulation system

● Electrical control system

The features for Quenching and tempering furnace for plate

The features for Quenching and tempering furnace for plate

● Simple operation: Automatic feeding & discharging, high degree of automatic.

● Fast heating speed, less oxidation skin, high efficiency, good heat treatment effect;

● Professional customized man-machine interface, highly user-friendly instructions;

● Unfirm heating and cooling, precise temperature adjustable control;

● Small temperature difference from surface to the core, very less deformation.

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)