Square billet heating furnace

Features:

| Material | Carbon steel |

| Suitable for | 60*60-240*240 billet |

| Process | Induction heating for rolling |

Product Detail

Application Video

Product Tags

Forever is specialized in designing and manufacturing square billet heating furnace for 15 years, which can save 30% than traditional heating furnace. We have produced thousands of induction billet heater with stable performance, uniform heating, no bending and no deformation. The square billet heating furnace has a 12-month warranty and provides you with free technical guidance for whole life.

The reference for Square billet heating furnace

| Product name | Square billet heating furnace |

| Brand | Forever |

| Material | Carbon steel |

| Suitable for | 60*60-240*240 billet |

| Heating way | Induction heating |

| Heating temperature | 1000-1200℃ |

| Power required | 100-8000KW |

Inductor manufacturing process for the square billet heating furnace:

The ratio of inductor inner diameter and the bars outer diameter is within a reasonable range, which is designed as per user’s parameters given. Our inductor heating coils are made with large T2 rectangular copper tubes after annealing heat treatment, pickling, water pressure test, baking, mica tape, glass ribbon double insulation, drying, knotting and assembling process. The inductor will be a Cuboid after finishing. It has good features of vibration and Entirety.

There is copper plate to protect at the both end of induction billet heater and it cancan effectively prevent electromagnetic radiation damage to the operators.

The inductor linning:

Adopting practical Sectional integral casting knotting process and eccentric knotting process to strength pressure resistant capability and increase the linning service life. At the same time, this process can make the bars place the middle of the inductor, which is beneficial to the uniformity of bar heating temperature, and more in line with the principle of proximity effect in the electromagnetic induction three effect.

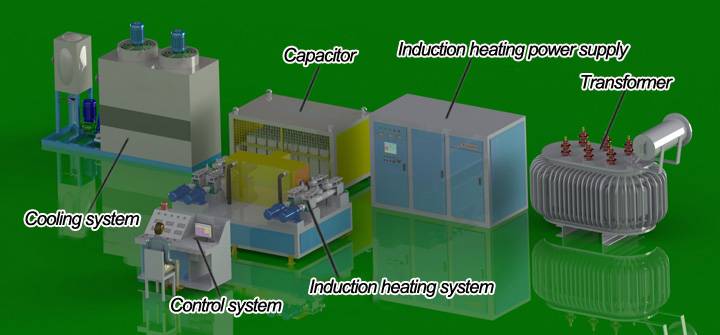

Equipment system work process

The complete set of equipment adopts PLC infrared temperature measurement temperature closed-loop control, and the billet only needs to go through the induction heating coil. The temperature compensation requirement is automatically completed by the system under the control of the infrared temperature measurement PLC.

Intelligent induction heating power supply technology

The intelligent induction heating power supply technology adopts semiconductor inverter device that takes thyristor as the power switching element and converts three-phase industrial frequency AC power into single-phase intermediate-frequency power (200-10000 Hz). It is mainly used for induction heating and heat treatment of steel bars, billet inline induction heating, surface quenching and so on.The core of the device is the control system. The domestic control system has experienced the stages of discrete components, small scale integrated circuits, and CPLD logic digital circuits. Our factory invested large funds in the upgrading of control system. In the June of 2015, we launched the fourth generation intelligent control system which adopts DSP+FPGA mode to improve the response speed and control precision control; Using the most advanced large scale integrated circuit has further enhanced the stability and anti-interference ability of main panel; Through industrial touch screen and direct communication to the main control board control, the interface is more concise. Digital setting for all the parameters has completely solved the problems of the temperature drift brought by previous analog line potentiometer and strong randomness. After putting into the market, the effect is good and is well received by the customers.

The MCSV7.6F IF power control system consists of three parts: main control panel, rectification trigger panel and inverter trigger panel. Its key component adopts DSP + FPGA composites integrated circuit and fully digital circuit implementation. All parameters can be digitally corrected on the touch screen or remote device which has characteristics of high reliability, strong anti-interference ability and quick response. The device has complete phase sequence adaptive circuit, no need synchronous transformer, no need to adjust the synchronous resistance, phase adjustment and synchronization are eliminated in the debugging. As long as the electrical and electronic devices are not damaged and the electrical and electronic components are firmly connected, it can guarantee the direct start and quickly enter the working state.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.