Stainless steel hardening manufacturers

Features:

| Material |

40Cr, 40MnB, S45C |

| Process | Hardening, quenching |

| Quenching temperature | 920-930℃ |

| Power required | 100-5000KW |

Product Detail

Application Video

Product Tags

Having more than 13 years of experience, Forever is specialized in designing and manufacturing stainless steel hardening furnace in China. Controlled by Siemens PLC, Our stainless steel hardening furnace can achieve automatic loading & unloading, heating and cooling process. The equipment can be produced as per user’s specific requirement such as workpiece size, capacity, hardening depth, cooling speed and so on.

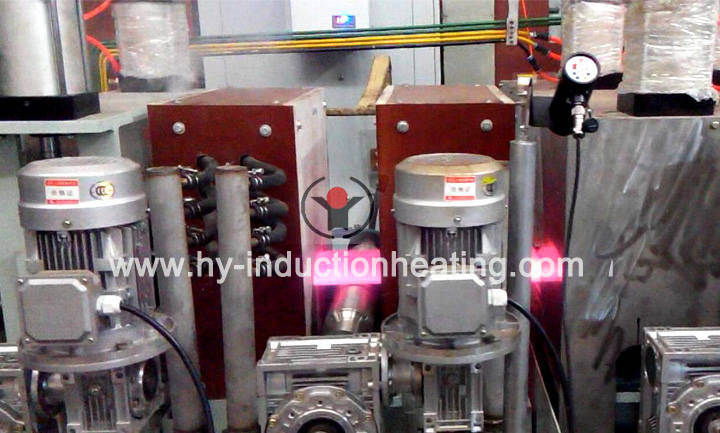

Site case for stainless steel hardening furnace

| Product name | stainless steel hardening furnace |

| Brand | Forever |

| Material |

40Cr, 40MnB, S45C |

| Process | Hardening, quenching |

| Quenching temperature | 920-930℃ |

| Power required | 100-5000KW |

Stainless steel hardening features are as follows:

(1) The surface has fine grains and high hardness. Induction quenching results in a very fine martensitic structure, which is 2 to 3 HRC higher than normal quenching, and the core basically maintains the organization and properties prior to treatment.

(2) The heating speed is fast and the heating time is very short, generally only a few seconds can be completed. The workpiece is not easily oxidized and decarburized, and the quenching distortion is also small.

(3) High thermal efficiency, high productivity, good production environment, and easy realization of mechanization and automation.

(4) The depth of the hardened layer is easy to control. By controlling the frequency of the current to control the depth of the hardened layer, the empirical formula is as follows: δ = (500 ~ 600) / f ^ 0.5 Where: δ – depth of hardened layer mm, f – frequency of current Hz.

If you are looking for induction quenching furnace for steel bars, pipes or plate, welcome to send us inquiry.

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)