Steel Billet Induction Forging Heating Furnace

Features:

1.Induction Power: DSP+IGBT Intelligent induction heating power,saving energy 10%-15%.

2.Process monitoring screen and Data logging and Archiving

3.Application:Heat Treatment and Heating for many kinds of metal parts.

Product Detail

Application Video

Product Tags

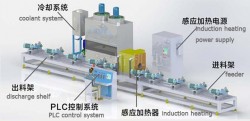

Steel billet induction forging heating furnace

Forever company dedicated to the research and development of energy-saving medium frequency Induction heating power supply more than 10 years. with the rising of the high power induction heating equipment production in recent years, the high power large equipment from my company all achieve the PLC automatic control, saving the labor cost and improving the work efficiency.Forever company manufacture the equipment according to user requirements and provide the best energy-saving schemes.

There are three problems which the buyers need to know before the buyers buying the Induction forging heating furnace:

1.The power of the steel billet induction forging heating furnace:

Typically, the greater the power of the induction heating forging equipment, the greater the size and weight of the workpiece can be heated or processed.

2.The frequency of the induction forging heating furnace:

The higher frequency means that closing to the position of the induction coil trend of skin effect is stronger (equal to the position of the magnetic lines of force distribution was more intensive) then heating surface of the workpiece is faster and to heat the smaller the workpiece.

Conversely, the lower frequency means that the induction coil in the vicinity of the trend of skin effect is weak, but it is quite far from the site of the induction coil magnetic field distribution and the coil near the magnetic flux distribution is similar and bring good diathermy effect, so means that can heating the thicker workpiece, so that the workpiece can simultaneously and uniformly heated. Intermediate frequency induction heating equipment is usually used in hot forging or melting or in the thickness of the thickness of the application.

3.The induction coil:

Sometimes, the power and frequency of induction heating equipment can meet the demand for heated workpiece. But if the shape of the workpiece is very special, maybe will lead to power and frequency is not suitable for the workpiece,so need to customize the special coil, and through experiment to obtain the desired optimal power and frequency of the workpiece.

The five characteristics of the Forever company’s steel billet induction forging heating furnace:

1.There are complete protection system.

The whole equipment were equipped the water temperature, water pressure, lack of phase, over current, over current, limited voltage / current limiting and starting over current devices to ensure the equipment start stable, protection reliable and fast and stable operation.

2.Automation degree is high.

The equipment can realize the full automatic unmanned operation, enhances the labor productivity;

3.Low energy consumption, no pollution and high heating efficiency

Compared with other heating methods, the energy consumption is reduced effectively, the labor productivity is high and no pollution.Equipment meet the requirements of environmental protection.

4.High temperature control precision heating evenly.

To ensure that the temperature of the heating core is small, the temperature control system can accurately control the temperature, to ensure the repeatability of the working process.

5.Simple replacement of medium frequency heating furnace.

According to the different dimensions of the processed workpiece, the induction furnace body with different specifications is required. The utility model is designed with a water and electricity quick change joint, which makes the furnace body to be replaced easily, quickly and conveniently.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.