Sucker rod quenching furnace

Features:

| Product name | Sucker rod quenching furnace |

| Brand | Yuantuo |

| Material | 29Mn5, 25MnCr, 25CrMnMo, 25MnV |

Product Detail

Application Video

Product Tags

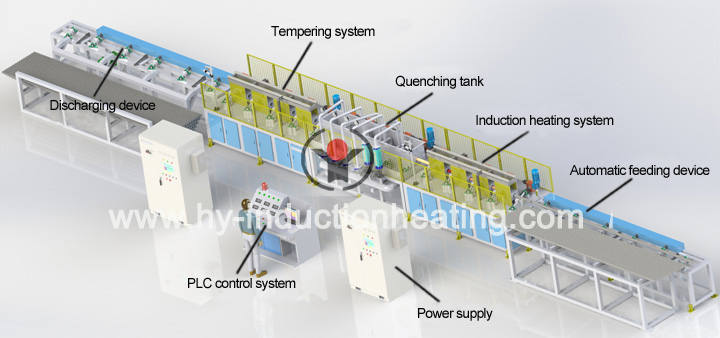

For sucker rod quenching furnace, our company have already successful cases for practical application. The sucker rod quenching furnace has achieved automatic loading, heating, quenching and discharging. We can also design sucker rod end heating furnace and tempering furnace as per user’s requirement.

For sucker rod quenching furnace, our company have already successful cases for practical application. The sucker rod quenching furnace has achieved automatic loading, heating, quenching and discharging. We can also design sucker rod end heating furnace and tempering furnace as per user’s requirement.

Site case for Sucker rod quenching furnace

| Product name | Sucker rod quenching furnace |

| Brand | Forever |

| Material | 29Mn5, 25MnCr, 25CrMnMo, 25MnV |

| Bar diameter | ≥ø20mm |

| Process | Quenching, tempering, annealing |

| Quenching temperature | 920-930℃ |

| Power required | 100-5000KW |

Sucker rod heat treatment equipment features:

1. No need to adjust the parameter for different size of sucker rod heat treatment. The power supply will automatically adjust the production parameters for different load.

2.Temperature closed-loop control through infrared thermometer detection, which can automatically adjust the power of intermediate frequency equipment in real time and provide users with accurate power control.

3.PLC control system, automatic feeding, heating, discharging during the whole process.

4.Touch screen display, temperature curve, water temperature alarm, furnace temperature, mechanical action, frequency control and other visualization operations are easy to learn.

5.Using pinch roller feeding method for more uniform and reliable feeding.

6. Energy saving more than 10%, harmonic pollution is very small.

PLC remote console for sucker rod quenching furnace

The system can record, save, inquiry and print the production parameters including heating temperature, production capacity and power supply running parameters etc. According to technical requirements, the system will automatically record and analysis the parameters changes and predict fault and alarm. Remote control the whole system and automatically generate various reports to achieve the traceability of the production process.

Welcome to contact us for bar heat treatment furnace details and videos.

Specialist of billet heating furnace and system in China; Glad to be your business partner in induction heating field.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.